How BIM Affects Masonry Construction

Building information modeling

By Chuck Eastman, Andres Cavieres

Throughout history, architecture and construction have relied on drawings from which to build. The drawings required multiple views in plan, section and elevation and multiple scales to represent what the building would be. Drawings were made with lines, arcs and text, which could only be interpreted by people.

At its most basic, Building Information Modeling (BIM) is the representation of building information in a computer-readable form. Because most building geometry is 3D, BIM models most geometry in 3D. Like the manufacturing industries that have already made this transition, BIM represents a building as a virtual building within the computer. Each part of the building is represented as an object and its shape, with needed properties and relations. End users, contractors and fabricators can walk through the model, seeing every part. Nothing is ambiguous.

There are many initial benefits of using BIM on a project:

- All drawings are consistent, with no errors where a change was made in one 2D view and not another.

- If the building model is complete, then it can support bills of material and quantity take-offs, that can be automated.

- A building model supports clash detection between all systems that are defined in 3D, eliminating change orders and on-site resolution of spatial conflicts. They can all be resolved virtually, using walk-throughs of the building as it is assembled in the computer.

Masonry and BIM

Masonry comes in many forms, from brick, concrete block and other types of modular elements, to natural stones with varied shapes. Masonry is almost always laid by hand, although there have been a few efforts of automatic layup.One of the main aesthetic advantages of masonry is that it allows a wide and rich scope of form possibilities, whether in load-bearing mode or as cladding. This feature can be intensively explored using BIM, making the evaluation of complex patterns and shapes an easier and more efficient approach.

The basic requirement of a BIM project is to define all subsystems in 3D, so that layouts can be checked by the computer and conflicts eliminated. Coordinating connections and pass-throughs are other important uses. If a building system is represented in 3D in its layout space and approved, the space is reserved, otherwise the space is free. Thus, the first step for all trades is to lay out the systems in a 3D building model, so possible conflicts can be resolved in the virtual building model, not the real building.

An important use of BIM is to develop smart (rule-based) layout and detailing. For example, the structural steel and precast industries have defined many of the design rules for these materials in BIM applications. The benefits are especially clear in automated connection design that can generate the appropriate connection based on the size and connection location of the pieces, and the structural loads being transferred.

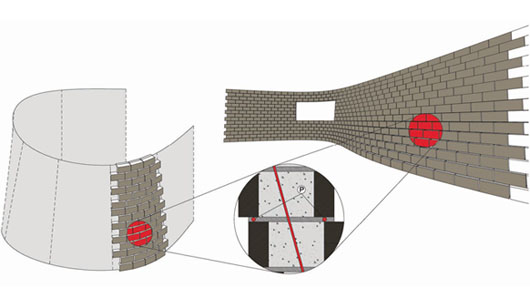

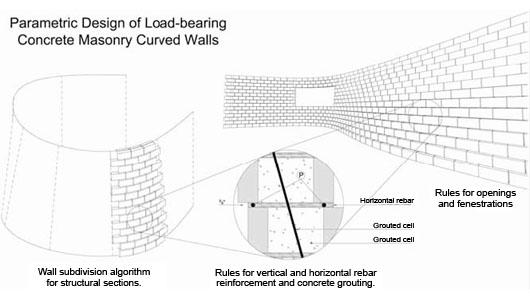

Despite these advantages, a BIM software specification for masonry does not yet exist. However, some exciting prototypes have been generated. One example is research on parametric design of concrete masonry buildings led by Prof. Russell Gentry at Georgia Institute of Technology.

Example: Parametric Design of Concrete Masonry Walls

This work, funded by the NCMA Education and Research Foundation, explores the potential of BIM technologies to promote innovation and efficiency in concrete masonry construction. The research explores ways in which parametric modeling can be applied to support the design and construction of curved load-bearing masonry walls. The final goal is to improve the design and construction processes by supporting easy definition and evaluation of design alternatives from the beginning, while providing automatic specification construction details [1].The current stage of the research focuses in the early stages of design, before the architect seeks the advice of a structural engineer or a contractor. A prototype system functions as a tool to guide and validate decisions according to structural and construction standard knowledge. The system translates this knowledge into a set of geometric rules which “bound” the curvatures of the masonry walls to those with admissible construction and structural solutions [2].

So far, rules for calculation and scheduling of block cuts, vertical rebar reinforcement in grouted cells and bond beams have been developed to allow for preliminary design of doubly-curved walls. Real-time feedback on wall configuration and reinforcement is provided as the model is built and the system also includes rules necessary for block wall description, including door and window openings. (See Figure 1.)

The Future

Because of its inherent advantages, building models are expected to become the standard representation of building used in construction in the future. New forms of contracts, capabilities for doing building code checks on BIM models, cost estimating and construction scheduling are all being interfaced with building models, with great benefits.In masonry, one could envision automated structural analysis, as outlined above. Accurate piece counts would be available. More complex geometries that have been fully analyzed could be designed with confidence. Eventually, robotic placement and mortaring machines may be invented and become available, using a building model of the layout to drive the machine’s work.

One day, the building model is expected to replace drawings, in the same way that the “horseless carriage” eventually was replaced by the automobile. A transition to Building Information Modeling and the transition of virtual design and construction is the future of construction.

About the Authors

Chuck Eastman directs the AEC Integration Lab at Georgia Tech, Atlanta, where he is a professor of architecture and computing. A pioneer in development of parametric modeling tools for the AEC. He also develops interoperability protocols and workflows. He is co-author with Paul Teicholz, Rafael Sacks and Kathleen Liston of the BIM Handbook, Wiley, 2008.

Andres Cavieres is assistant professor in Digital Media and Design Studio. Facultad de Arquitectura y Urbanismo. Universidad de Chile. Andres has worked in several Chilean architectural offices and as independent architect. He received his bachelor’s degree in architecture from Universidad de Chile in 2002. Currently, he is a Ph.D. student in design computing and graduate research assistant at the Advanced Wood Products Laboratory - AWPL. College of Architecture - Georgia Institute of Technology.

References

Cavieres, A., Gentry, R., Al-Haddad, T., Parametric Design of Masonry Buildings - Embedding Construction Knowledge into Design Models, Proceedings of the 8th International Seminar on Structural Masonry (ISSM), Istanbul Technical University, Turkey, 2008, pp. 39 – 47.Gentry, R., Cavieres, A., Al-Haddad, T., Parametric Design, Detailing and Structural Analysis of Doubly-curved Load-bearing Block Walls, 11th Canadian Masonry Symposium, Department of Civil Engineering, McMaster University. Toronto, Ontario, Canada, May 31 – June 3, 2009.