October 22, 2010 9:00 AM CDT

Most brick ties have been developed to comply with a stiffness criterion of 2,000 pounds per inch as encouraged by the Brick Industry Association and the Western States Clay Products Association. This is a critical standard, due to the veneer reaction to wind pressure. The wall tie system must be capable to transfer the live load to the parent structure with minimal veneer deflection. Insufficient and/or inadequate ties and fasteners can exacerbate the wall deflection and allow for deficiencies in the performance-based expectations of the veneer, compromising water tightness and air permeability. An unanticipated weakness of a wall tie configuration can be the result of a less then adequate fastener. The analogy of “you’re only as strong as your weakest link” plays true in this scenario.

The veneer can be attached to a host of building elements, which can include concrete, masonry, cold formed metal stud or wood stud, and structural steel – the task is to select the appropriate fastener. Keep in mind that once the veneer is constructed, the fastener connection is not serviceable, leading to multiple questions that need to be answered prior to construction. What type of fastening system should be used? What cautions should the engineer or installer be aware of regarding various fastener types? How effective is the fastener for the application? Is the fastener’s stiffness as good as the tie selected? How sensitive to installation challenges are the various types of anchors or fasteners?

The connection methods are numerous, but any anchorage must resist the veneer loads. The first step is to quantify the order of magnitude of loads for the fastener to resist. Adjustable ties spaced at 1 per 2.67 square feet are expected to resist a tension and compression load. The basic live load as calculated can be as low as 21 psf for a non-essential structure based on 90 mph wind speed. The resulting force is 56 pounds tension and compression. Applying a 4:1 safety factor, an anchor allowable load greater than 225 pounds would be useful and marginally acceptable. If a seismic condition exists, the live load can be 70 pounds or greater and the allowable load for the fastener can be 280 pounds.

Torque applied anchors are an ideal solution for the plate attachment. Besides providing a measurable clamping force, the installed anchor can be inspected. Applying a 4 foot-pound (48-50 inch-pound) torque can produce a preload greater then 900 pounds. This is a typical installed torque for 1/4-inch torque type anchors. Since the preload exceeds the allowable load and allows for creep and relaxation of the installed torque (usually 35 to 50 percent), the choice would be acceptable (check with anchor manufacturer regarding the appropriate installed torque and the resulting induced clamping force). Stud-type expansion anchors can take four to six turns of the nut to achieve the installation torque. The stud projection from the plate surface could be 1/4- to 3/8-inch above the surface of the nut. The total anchor projection distance of 1/2- to 3/4-inch can interfere with the placement of insulation or the vertical travel of the adjustable tie in the base plate. Therefore, a torque activated anchor having a hex head finish is best.

The use of anchors other then torque-controlled expansion has limited appeal. A nail drive system does not draw the plate tight to the concrete or masonry surface. If not properly inserted and activated the anchor can expand prematurely, and the plate connection would be loose to the surface. This will have a negative impact on the free play of the tie and result in excessive deflection. Except for a visual identification, a physical inspection is not possible that would indicate the tie system is secured to the building. This would be true of any nail or hammer driven anchor. The toggle is torque applied, but the hole size required for a 1/4-inch bolt is 3/4-inch in a hollow application such as CMU. A large drilled hole such as this will play havoc with air and water permeance.

The minimum finish of any screw should be zinc plating. The application of a polymer coating in lieu of just zinc can enhance corrosion protection and provide a long lasting connection.

Another cost effective selection is to use a self-drilling/self-tapping 410 stainless-steel screw. They are hardened for strength and durability, while still possessing essential alloys for corrosion protection. These characteristics will allow the screw to self-drill a precise pilot hole for the self-threading action of the screw, provide corrosion protection, and offer material strength properties that create an effective long-term fix to the steel stud. Incorporating a sealant washer will keep moisture from influencing the effects of differing material when applied to non-stainless ties.

Anchored Veneer: How Good is Your Fastener?

Connectors, anchors and fasteners

Brick ties connect with concrete, metal stud and masonry structures.

Brick veneer/cavity wall construction is a popular building practice. The aesthetic value, quality image, and the constructability of brick veneers lends to its diverse application. The advantages associated with the use of brick veneer are numerous, and warrant a dedicated discussion. However, the air barrier integrity of the veneer system has become a significant entity in the design and construction of brick veneered structures. An area of interest amongst design professionals and building owners is the awareness of energy savings and LEED recognition associated with the masonry. The design team and contractor are expected to construct the brick veneer maintaining focus on the essentials of air barrier integrity and moisture control. An improper brick tie and fastener combination can lead to unexpected compromises in the veneer stiffness and potential moisture and air leakage issues.Most brick ties have been developed to comply with a stiffness criterion of 2,000 pounds per inch as encouraged by the Brick Industry Association and the Western States Clay Products Association. This is a critical standard, due to the veneer reaction to wind pressure. The wall tie system must be capable to transfer the live load to the parent structure with minimal veneer deflection. Insufficient and/or inadequate ties and fasteners can exacerbate the wall deflection and allow for deficiencies in the performance-based expectations of the veneer, compromising water tightness and air permeability. An unanticipated weakness of a wall tie configuration can be the result of a less then adequate fastener. The analogy of “you’re only as strong as your weakest link” plays true in this scenario.

The veneer can be attached to a host of building elements, which can include concrete, masonry, cold formed metal stud or wood stud, and structural steel – the task is to select the appropriate fastener. Keep in mind that once the veneer is constructed, the fastener connection is not serviceable, leading to multiple questions that need to be answered prior to construction. What type of fastening system should be used? What cautions should the engineer or installer be aware of regarding various fastener types? How effective is the fastener for the application? Is the fastener’s stiffness as good as the tie selected? How sensitive to installation challenges are the various types of anchors or fasteners?

Dovetail anchor with excessive free play greater than 3/8-inch.

Tie Selection

Adjustable ties are preferred. They can be a base plate with a “v” or triangular tie, a plate and two-leg pintle, or a single post and tie system. The selection is a function of the wall make-up, and whether waterproofing/flashing and insulation has been applied. Ideally, the base plate should make firm contact with the concrete, masonry, or sheathing in order to assure both compression load transfer and that a secure connection is made. Extended legs for piercing the insulation are taxing to maintain in a perpendicular installation. Also note that two-screw installations required by manufacturers are not for redundancy, but performance. A loss of one screw in a two-screw set renders the tie compromised, and remediation is required. Also, the tie system must have holes in the base plate large enough to accommodate the selected anchor. For instance, a 5/16-inch diameter hole would be the required hole size for a 1/4-inch anchor.The connection methods are numerous, but any anchorage must resist the veneer loads. The first step is to quantify the order of magnitude of loads for the fastener to resist. Adjustable ties spaced at 1 per 2.67 square feet are expected to resist a tension and compression load. The basic live load as calculated can be as low as 21 psf for a non-essential structure based on 90 mph wind speed. The resulting force is 56 pounds tension and compression. Applying a 4:1 safety factor, an anchor allowable load greater than 225 pounds would be useful and marginally acceptable. If a seismic condition exists, the live load can be 70 pounds or greater and the allowable load for the fastener can be 280 pounds.

Concrete and Masonry Fastening Applications

Brick tie products typically specified are dovetail slots and dovetail anchors or hook and eye reinforcement for the concrete and masonry applications respectively. If typical product placement and serviceability are effected by installation issues, or a veneer is to be added to an existing concrete or masonry wall, an alternate veneer anchor method will be required. Once selected, how is it fastened to the concrete or masonry?

From left to right: Typical torque-type anchor, typical threaded fastener, typical nail drive expansion, typical toggle

Fastener Selection

Anchors to concrete or masonry can be torque activated, hammer set expansion types, threaded screws, power actuated pins, or hammer driven nails. Depending upon the tie system selected, the length or type of fastener must comply with the thickness of the base plate to be attached, plus the minimum embedment required for the fastener to achieve the loads induced. Since this fastener must partner with a plate or tie assembly, the functional and material compatibility with the tie is important.Torque applied anchors are an ideal solution for the plate attachment. Besides providing a measurable clamping force, the installed anchor can be inspected. Applying a 4 foot-pound (48-50 inch-pound) torque can produce a preload greater then 900 pounds. This is a typical installed torque for 1/4-inch torque type anchors. Since the preload exceeds the allowable load and allows for creep and relaxation of the installed torque (usually 35 to 50 percent), the choice would be acceptable (check with anchor manufacturer regarding the appropriate installed torque and the resulting induced clamping force). Stud-type expansion anchors can take four to six turns of the nut to achieve the installation torque. The stud projection from the plate surface could be 1/4- to 3/8-inch above the surface of the nut. The total anchor projection distance of 1/2- to 3/4-inch can interfere with the placement of insulation or the vertical travel of the adjustable tie in the base plate. Therefore, a torque activated anchor having a hex head finish is best.

The use of anchors other then torque-controlled expansion has limited appeal. A nail drive system does not draw the plate tight to the concrete or masonry surface. If not properly inserted and activated the anchor can expand prematurely, and the plate connection would be loose to the surface. This will have a negative impact on the free play of the tie and result in excessive deflection. Except for a visual identification, a physical inspection is not possible that would indicate the tie system is secured to the building. This would be true of any nail or hammer driven anchor. The toggle is torque applied, but the hole size required for a 1/4-inch bolt is 3/4-inch in a hollow application such as CMU. A large drilled hole such as this will play havoc with air and water permeance.

Keys to Fastener Selection for Masonry or Concrete

- Determine loading requirements for the application and select an anchor that can meet or exceed the applied loads

- Size matters – be certain the anchor selected fits the base plate holes and is adaptable to the base material (concrete, brick, block, etc.)

- Select a torque controlled expansion type anchor

- Select a torque activated expansion anchor having a hex head finish

- Select an anchor with a compatible finish, similar to the tie assembly

- Establish a minimum installed torque that meets or exceeds the applied loads

- Avoid non-metallic anchors

- Avoid hammer or power driven anchors, especially in hollow CMU.

- Check for edge distance and center-to-center distance criteria for placement and performance assurance

Fastener Selection for Metal Stud

Cost-effective connections to the steel stud have limited options. Preferably, self-drilling/self-tapping screws are ideal. The screw incorporates a drilling tip designed to provide a pilot hole for optimum thread engagement to the steel. Sheet metal screws, which are self-tapping require a pre-drilled pilot hole and are acceptable, however the installation method requiring two drilling operations usually limits the appeal from a cost and efficiency point of view. The performance of the self-tapping screw is also dependent on the pilot hole drill size used. A 300 series stainless steel sheet metal screw or self-tapping screw may be more cost effective than using bi-metal self-drilling tips on a 300 series stainless self-drilling screw, and possibly worth evaluating.

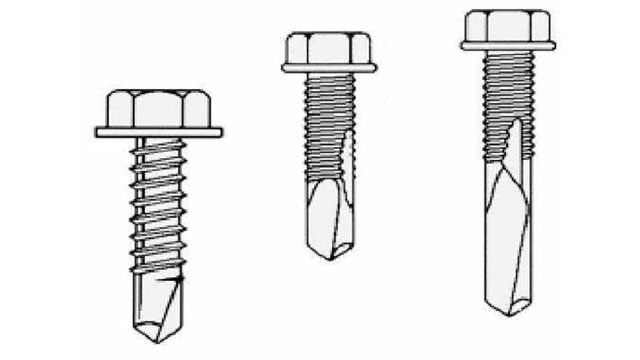

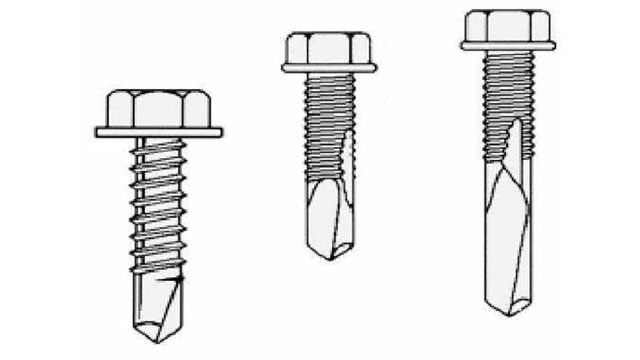

Drill point length varies, depending upon the screw size and point type.

Screw Drill Tip Choice

The self-drilling screws are available with different drill points. The drill point selection is based on the thickness of steel encountered. For example, in a 16-gauge stud application, a #2 (0.035-inch to 0.140-inch thick steel working range) and #3 (0.036-inch to 0.210-inch minimum steel thickness) is acceptable. The predominant screws available in lengths common in our industry are #3 point. The same size screw with a differing drill point can affect screw tension capacity as much as 10 percent less with the larger point size. Consult with the manufacturer for the appropriate size/capacity information if needed. The length of the point varies by screw size also. In a #2 point #10 screw, the drill point length can be 13/64-inch and for the #2 point #12 screw, the drill point length can be 1/2-inch. A #3 point can be up to 5/16-inch long for a #12 or 1/4-inch screw. The dimensions are relevant in order to select the proper screw length.Screw Size – Diameter

Selecting the screw size (diameter) then becomes the next condition. The BIA recommends a minimum #10 screw be used. A #12 and 1/4-inch diameter are also capable to satisfy the working load environment. The #10 screw has a diameter of 0.190-inch and usually 16 threads per inch. A #12 screw is 0.216-inch in diameter and has 14 threads per inch as does the 1/4-inch screw size. The functional requirements of the screw selection will determine the size based on capacity demand.Screw Size – Length

The minimum length of screw required for an application is a function of:- The tie plate thickness (can range 0.60-inch to 0.125-inch) PLUS

- The stud thickness (0.056-inch for 16-gauge) PLUS

- The sheathing thickness PLUS

- Three threads (minimum threads piercing through the steel, 3/16-inch for #10, and 1/4-inch for #12 and 1/4-inch screws) PLUS

- The Drill Point length (13/64-inch for #10, and 1/2-inch for #12) PLUS

- The sealant washer thickness (1/8-inch)

- .06+.056+.625+.188+.203+.125 = 1.257 inch, or 1-1/2 inch

- .06+.056+.625+.250+.500+.125 = 1.616 inch, or 1-5/8 inch

HWD self-drill/self-tap screw (left), HWD self-drill/self-tap screw with sealant washer (right)

Screw Head Type

A Hex Washer Head (HWD) screw (usually 5/16-inch hex) is the preferred style. It is efficient to drive and its profile is relatively low. Pan head and Flat head styles are also available but more tedious to install and the aesthetic value is not warranted. It is important to incorporate a sealant washer as a means to restrict moisture and air flow through the connection. It also provides a material separation in the event a stainless steel base plate is used. This would avoid a galvanic reaction due to the differential materials.Screw Performance

The Steel Stud Manufacturer’s Association publishes a conservative allowable fastener performance in 16 gauge stud as 137 pounds and 156 pounds tension per screw for the #10 and #12, respectively (without reference to drill point effects). The individual manufacturer’s pull-out data for the selected screw sizes is a more realistic approach for capacity consideration. For example, allowable tension loads varied from 200 pounds to 800 pounds from seven different manufacturers. Selecting the screw to use is based on the performance expectations and the quantity per tie required by the tie manufacture. Single fastener designed ties are cost efficient, and quick research regarding the screw performance will provide the appropriate strength for the connection and less breaches in the air barrier. Based on the live load determined above, the resulting force of 56 pounds tension and compression would produce a safety factor of 2.5:1 and 2.8:1 for the screw sizes listed by the SSMA. If a seismic condition exists, the live load can be 70 pounds or greater and the resulting safety factor can be 2:1 or 2.2:1.Screw Material and Finish

Heat-treated carbon steel is the usual material selected to manufacture the self-drilling/self-tapping screws. This process creates a hard and durable wear surface to drill a pilot hole and cut the threads in the stud. Some manufacturers’ incorporate a dual heat treat process, which creates a grade 5 load-bearing surface and a good wearing surface. The lead portion of the screw is then harder for good drilling efficiency. They are excellent for durability, and embrittlement issues are abated.The minimum finish of any screw should be zinc plating. The application of a polymer coating in lieu of just zinc can enhance corrosion protection and provide a long lasting connection.

Another cost effective selection is to use a self-drilling/self-tapping 410 stainless-steel screw. They are hardened for strength and durability, while still possessing essential alloys for corrosion protection. These characteristics will allow the screw to self-drill a precise pilot hole for the self-threading action of the screw, provide corrosion protection, and offer material strength properties that create an effective long-term fix to the steel stud. Incorporating a sealant washer will keep moisture from influencing the effects of differing material when applied to non-stainless ties.

Screw Installation

Typically, a variable speed screw gun is used with depth indicating sockets to drive and seat the screw. A tool with a maximum 2,500 rpm and 4 amp power is sufficient, but not overwhelming, to create the torque and drive to seat the screw. Too large a tool will strip or snap the screw. Too small a tool will challenge labor efficiencies and risk improper setting torque (too low). This can and will make the plate assembly less than secure to the base material.Keys to Screw Selection for a Metal Stud

- Self Drilling – Self Tapping Screw

- #12 Screw with a #3 point

- Length no less than 2 inches

- Hex Washered Head (HWH) with Sealant washer

- No less the 200 pounds tension allowable

- Polymer coated, or

- Stainless Steel

Originally published in Masonry magazine.

About the Author

Stephen Getz, BSCE, is president of Construction Tie Products, Inc., a manufacturer and supplier of masonry ties, stone anchors, masonry restoration anchors and fasteners for the masonry industry. For more information, visit www.ctpanchors.com.