Our Masonry Code and Specification: Where do they come from?

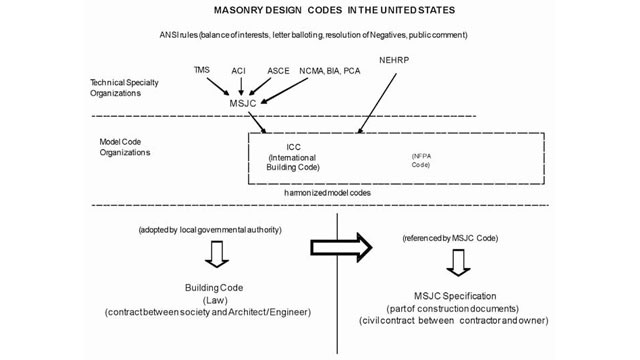

From the viewpoint of a designer or a contractor involved in the design and construction of a particular hypothetical building, the process shown in Figure 1 is applied from the bottom,up. If the building is in Austin,Texas, for instance, the designer is required to follow the legally adopted building code,which will soon be the 2009 version of the International Building Code (IBC 2009). The 2009 IBC references the 2008 Masonry Standards Joint Committee (MSJC) Code (MSJC 2008a), which, in turn, references the 2008 MSJC Specification (MSJC 2008b). Because it is referenced by the legally adopted building code, the 2008 MSJC Code becomes the law for designers. Because the 2008 MSJC Code refers to the 2008 MSJC Specification, that Specification must become part of the construction documents. The construction documents include general terms and conditions, plans, and specifications. They must include a quality assurance program at least as rigorous as that required by the MSJC Code and Specification. They become a civil contract between the contractor and the owner.

The First Step – The Masonry Standards Joint Committee

As shown at the top of Figure 1, the MSJC Code and Specification is produced by the Masonry Standards Joint Committee, a national committee that operates under rules approved by the American National Standards Institute (ANSI).Those operating rules include the following:

- Balance of interests (producer, user and general interest);

- Written balloting of proposed provisions, with defined requirements for a successful ballot;

- Resolution of negative votes.Negative votes must be discussed and found non-persuasive before a ballot item can pass. A single negative vote, if found persuasive, can prevent an item from passing;

- Public comment.After being approved within the technical specialty organization, the mandatorylanguage provisions must be published for review and comment by the general public. All comments are responded to, but do not necessarily result in further modification.

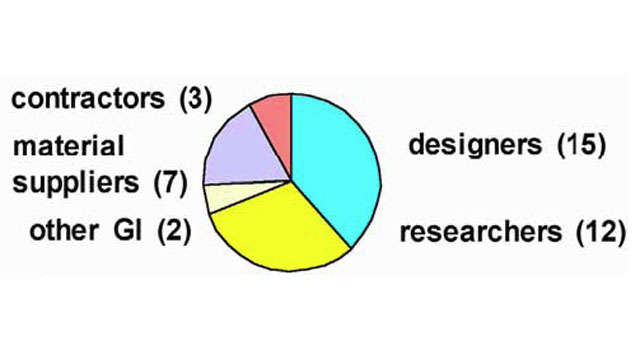

The MSJC’s lead sponsor is The Masonry Society, www.masonrysociety.org, and its other sponsors are the American Concrete Institute, www.aci-int.org, and the American Society of Civil Engineers, www.asce.org. Information about membership is available on the TMS website. The MSJC meets twice each year, in conjunction with TMS meetings, and its meetings are open to the public. The MSJC Code and Specification is published at three-year cycles. The next edition will be published in 2011, and is now undergoing public comment. Input to the MSJC comes from a variety of masonry industry organizations, including the Portland Cement Association (PCA); the National Concrete Masonry Association (NCMA); the Brick Industry Association (BIA); the National Lime Association (NLA); the Expanded Shale Clay and Slate Institute (ESCSI); the International Masonry Institute (IMI); the Mason Contractors’Association of America (MCAA); and the Autoclaved Aerated Concrete Products Association (AACPA).

The Next Step – Model-Code Referencing

The next step in the masonry code-development process is the referencing of the MSJC Code and Specification by model codes. Until about 10 years ago, the United States had three model codes: the Uniform Building Code, the Standard Building Code, and the Basic Building Code. Beginning in 2000, those so-called “legacy” model codes were replaced by a single, harmonized International Building Code, whose latest edition was published in 2009 (IBC 2009).Although the IBC is the dominant model code in the United States at the present time, another model code has been developed by the National Fire Protection Association, and is used in a few jurisdictions in the U.S.The International Building Code is published by the International Code Council (ICC), www.iccsafe.org. It is composed primarily of building officials, although designers, contractors, product suppliers, code developers, and end-users also can be members. Decisions about referencing technical documents such as the MSJC Code and Specification (possibly with amendments) are made at a series of nationwide hearings, scheduled during the development of each new edition of the IBC.

The Final Step – Adoption of Model Code by the Local Jurisdiction

In each local jurisdiction, the legally established authority (usually a city council or county board of supervisors) is responsible for adopting a model code. For most jurisdictions, the choice is which edition of the IBC to adopt. A model code is sometimes adopted with amendments.The Role of the Federal Government

Although the federal government is not empowered by the U.S. Constitution to develop a national building code, it does provide input to the model-code process, particularly in the area of seismic design. The Federal Emergency Management Agency (FEMA) has jurisdiction over the National Earthquake Hazard Reduction Program, and develops and periodically updates the NEHRP provisions, a set of recommendations for earthquake-resistant design, including the design of masonry structures. The latest edition of those provisions was published in 2009 (NEHRP 2009). Those provisions are published by the Building Seismic Safety Council (BSSC), which operates under a contract with the National Institute of Building Sciences (NIBS).How Mason Contractors Can Participate in the Code Process

Mason contractors are encouraged to participate in each step of the code-development process outlined above.In the first step (the MSJC), mason contractors can communicate with the lead sponsor (the Masonry Society); they can attend MSJC meetings, and, in particular, the meetings of the Construction Requirements Subcommittee, which is primarily responsible for the MSJC Specification; and they can communicate their interests and concerns to MSJC members, particularly mason contractor members.

In the second step (model codes),Mason contractors can visit the websites of model-code organizations such as the International Code Council; they can attend or view model code hearings live on line; and they can phone or email the members of model-code committees.

In the third step (local jurisdiction), mason contractors can work with local elected officials for the adoption of modern codes and specifications for masonry design and construction.

References

IBC 2009: International Building Code, 2009 Edition, International Code Council, Washington, D.C., 2009.MSJC 2008a: Building Code Requirements for Masonry Structures (TMS 402-08/ACI 530-08/ASCE 5-08), The Masonry Society, Boulder, Colo., the American Concrete Institute, Farmington Hills, Mich., and the American Society of Civil Engineers, Reston, Va., 2008.

MSJC 2008b: Specification for Masonry Structures (TMS 602-08/ACI 530.1-08/ASCE 6-08), The Masonry Society, Boulder, Colo., the American Concrete Institute, Farmington Hills, Mich., and the American Society of Civil Engineers, Reston, Va., 2008. NBC: National Building Code, Building Officials and Code Administrators International, Country Club, Ill.

NEHRP 2009: NEHRP (National Earthquake Hazards Reduction Program) Recommended Provisions for the Development of Seismic Regulations for New Buildings (FEMA P-750), Building Seismic Safety Council, Federal Emergency Management Agency, Washington, D.C., 2009.

Originally published in Masonry magazine.

About the Author

Richard E. Klingner, Ph.D. is the L. P. Gilvin professor of civil engineering at the University of Texas at Austin, where he specializes in the behavior and design of masonry, particularly for earthquake loads. He is also the author of Masonry Structural Design and the former chair of the Masonry Standards Joint Committee (MSJC).

In this article, the process used to produce our masonry design code and specification in the United States is reviewed, with emphasis on how that process affects mason contractors. Mason contractors are encouraged to participate in that process.