August 3, 2011 7:00 AM CDT

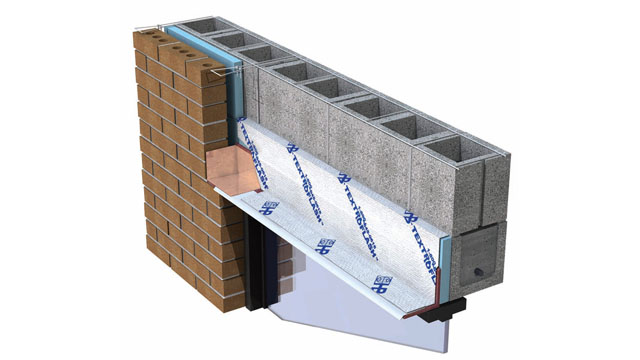

Today, we use the phrase “moisture management in the building envelope” to describe a total-system approach to designing, detailing and specifying products that work together to prevent moisture intrusion and effectively direct any moisture within the wall to the outside. At present, the brick exterior of a cavity wall system is viewed strictly as the veneer of the wall assembly, rather than an actual barrier to moisture.

Considering this, we must look at cavity wall design and construction much differently than we have in the past. The concept of rain-screen design is where the “true” barrier in most wall systems today actually is the outer face of the back-up wall. With this in mind, controlling all types of moisture in the wall assembly takes on an even greater importance.

A major facet of building envelope regarding moisture is the thru-wall flashing system. Today, we are, correctly, viewing flashing as a complete system that includes numerous component options, including drip plates, termination bars, mortar collection devices, pre-formed corners, weeps and vents.

Aesthetics can be a major problem with these drip plates. So, today, newer drip plates are being manufactured with durable UV-resistant plastics that come in various colors to match a mortar or brick color. As steel-stud wall assemblies continue to become more commonplace, flashings are being adhered onto sheathing materials, requiring the use of a termination bar with a sealed top edge that prevents moisture from migrating behind the flashing material.

When discussing thru-wall flashing materials, one of the most important criteria should be the “installability” of the material, with the success of the system largely related to the installation in the field. Certainly, a good, high-quality material is essential. But it can be argued that the ability of the contractor to be able to work with the material and create a total watertight system, including numerous detail points at inside/outside corners, head and sills of window openings, elevation changes and other transitions, is just as essential. While the tried-and-true products of the past still can provide us with quality installations, we should not ignore the many improved, user-friendly products on the market today.

A vital aspect of moisture management actually is getting the moisture out of the wall. From the early days of cavity wall construction, architects and masons saw the need for effective drainage. This moisture drainage is achieved through the use of weeps located at each flashing location. Traditionally, plastic tubes and cotton cords were installed 16 inches on center. This configuration is giving way to full-height weeps made of honeycomb plastic, aluminum or synthetic mesh, spaced 24 inches on center.

The concept of ventilating the cavity air space is another major development in our industry related to moisture management. The use of vents at the top of a cavity wall section combined with the weeps at the bottom of the section allow for the circular movement of air in and out of the cavity, allowing materials within the wall to dry out and provide the added benefit of more effective movement of moisture out of the cavity. Ventilation can be accomplished through the use of similar, full-height, weep-type materials or open-head joints. This ventilation concept also lowers the air pressure differential between the outside air and the air with the wall assembly, thus slowing down the moisture drive into the wall.

In southern climates, ventilation systems help to release excessive heat buildup within the cavity. The masonry industry now recommends a two-inch air space behind the brick to provide a clean, open area for any moisture to more easily work its way to the bottom of the cavity, onto the flashing material and out through the weeps. Some veneer products, especially stone, can have varying thicknesses, making it virtually impossible to maintain a consistent two-inch air space over the entire wall. Options like woven mesh material or drainage panels installed over the entire wall can provide a clear pathway for moisture to escape cavities that are considerably less than the recommended two-inch air space.

Obviously, masonry wall design has become increasingly complex, with so many components coming together in the wall assembly. Designers and specifiers must look at all of these materials and how they interact with each other to provide a complete system approach that can accomplish all the requirements of a current structure. Component manufacturers must be keenly aware of how all of these products must effectively function together, understanding products in addition to their own. Contractors have the ultimate responsibility of constructing these complicated wall systems to manage moisture and give the owner a building that meets today’s high-performance standards.

Addressing moisture infiltration

Flashing and drainage

By Chris Bupp

Window head with end dam (flashing should extend at least 6 inches passed the opening on both sides).

As masonry wall design continues to evolve into the 21st century, terms like air and vapor barriers, steel stud assemblies, rigid insulation, semi-rigid insulation, batt insulation, ventilation with weeps and vents, mortar collection devices, clear air space, and oversize masonry units all are employed to describe today’s masonry wall. Add to that a list of adjectives like green, high-performance and sustainable, and it becomes obvious that masonry has gone through quite a transformation. What has been consistent is a concern over the damaging effects of moisture infiltration.Today, we use the phrase “moisture management in the building envelope” to describe a total-system approach to designing, detailing and specifying products that work together to prevent moisture intrusion and effectively direct any moisture within the wall to the outside. At present, the brick exterior of a cavity wall system is viewed strictly as the veneer of the wall assembly, rather than an actual barrier to moisture.

Considering this, we must look at cavity wall design and construction much differently than we have in the past. The concept of rain-screen design is where the “true” barrier in most wall systems today actually is the outer face of the back-up wall. With this in mind, controlling all types of moisture in the wall assembly takes on an even greater importance.

A major facet of building envelope regarding moisture is the thru-wall flashing system. Today, we are, correctly, viewing flashing as a complete system that includes numerous component options, including drip plates, termination bars, mortar collection devices, pre-formed corners, weeps and vents.

Flashing cut flush

Technology and innovation have brought many new and improved flashing and moisture protection products to market that can withstand high temperatures and ultraviolet exposure. Non-asphaltic adhesives provide distinct advantages over their older rubberized asphalt counterparts, notably, easier installations of the contractor in the field. Copper flashings remain a popular choice among designers, and improvements have been made with clear protective coatings over the copper materials in lieu of asphalt coatings. Newer self-adhesive copper materials are available as well. With the Brick Industry Association stating in its Technical Notes, “It is imperative that flashing be extended at least to the face of the brickwork,” UV-resistant membranes are becoming a more popular choice. Still, the masonry industry recommends the use of a drip plate to extend the flashing beyond the outer face of the brick. This is normally accomplished with a stainless-steel drip plate that extending about 3⁄8-inch beyond the face and turned down on a 30-degree angle with a hemmed edge.Aesthetics can be a major problem with these drip plates. So, today, newer drip plates are being manufactured with durable UV-resistant plastics that come in various colors to match a mortar or brick color. As steel-stud wall assemblies continue to become more commonplace, flashings are being adhered onto sheathing materials, requiring the use of a termination bar with a sealed top edge that prevents moisture from migrating behind the flashing material.

When discussing thru-wall flashing materials, one of the most important criteria should be the “installability” of the material, with the success of the system largely related to the installation in the field. Certainly, a good, high-quality material is essential. But it can be argued that the ability of the contractor to be able to work with the material and create a total watertight system, including numerous detail points at inside/outside corners, head and sills of window openings, elevation changes and other transitions, is just as essential. While the tried-and-true products of the past still can provide us with quality installations, we should not ignore the many improved, user-friendly products on the market today.

A vital aspect of moisture management actually is getting the moisture out of the wall. From the early days of cavity wall construction, architects and masons saw the need for effective drainage. This moisture drainage is achieved through the use of weeps located at each flashing location. Traditionally, plastic tubes and cotton cords were installed 16 inches on center. This configuration is giving way to full-height weeps made of honeycomb plastic, aluminum or synthetic mesh, spaced 24 inches on center.

Base flashing detail with a drip edge

These products are installed into the vertical head joint of the brick course on top of the flashing. Many of these “next-generation” weeps are made of materials that come in various colors to match a mortar color. The cavity area must be kept open and unclogged at the flashing line to allow any accumulated moisture to fall to the weeps via gravity, and exit out of the wall. For many years, pea gravel was the product of choice for drainage and keeping weep holes open and free flowing. In time, pea gravel was recognized as only serving to dam the mortar droppings up higher in the cavity. It did not maintain an open path for water passage. This revelation opened the door for innovation, and new products were introduced with synthetic mesh materials with a 90 percent open weave and cut into patented shapes to catch and break up mortar droppings at two distinct heights. This ensures a clear path for water to migrate around the droppings and out of the wall.The concept of ventilating the cavity air space is another major development in our industry related to moisture management. The use of vents at the top of a cavity wall section combined with the weeps at the bottom of the section allow for the circular movement of air in and out of the cavity, allowing materials within the wall to dry out and provide the added benefit of more effective movement of moisture out of the cavity. Ventilation can be accomplished through the use of similar, full-height, weep-type materials or open-head joints. This ventilation concept also lowers the air pressure differential between the outside air and the air with the wall assembly, thus slowing down the moisture drive into the wall.

In southern climates, ventilation systems help to release excessive heat buildup within the cavity. The masonry industry now recommends a two-inch air space behind the brick to provide a clean, open area for any moisture to more easily work its way to the bottom of the cavity, onto the flashing material and out through the weeps. Some veneer products, especially stone, can have varying thicknesses, making it virtually impossible to maintain a consistent two-inch air space over the entire wall. Options like woven mesh material or drainage panels installed over the entire wall can provide a clear pathway for moisture to escape cavities that are considerably less than the recommended two-inch air space.

Obviously, masonry wall design has become increasingly complex, with so many components coming together in the wall assembly. Designers and specifiers must look at all of these materials and how they interact with each other to provide a complete system approach that can accomplish all the requirements of a current structure. Component manufacturers must be keenly aware of how all of these products must effectively function together, understanding products in addition to their own. Contractors have the ultimate responsibility of constructing these complicated wall systems to manage moisture and give the owner a building that meets today’s high-performance standards.

Originally published in Masonry magazine.

About the Author

Chris Bupp is architectural and educational service director for Hohmann and Barnard.