January 16, 2012 7:00 AM CST

The hole/whole story – the more complete story – is that some exterior building surfaces of the exterior building envelope are responsible for more than just moisture management. These responsibilities include aesthetics, structural support, signage support, mechanical support and protection (veneers acting as shields). In addition to all these responsibilities, they also have to manage moisture.

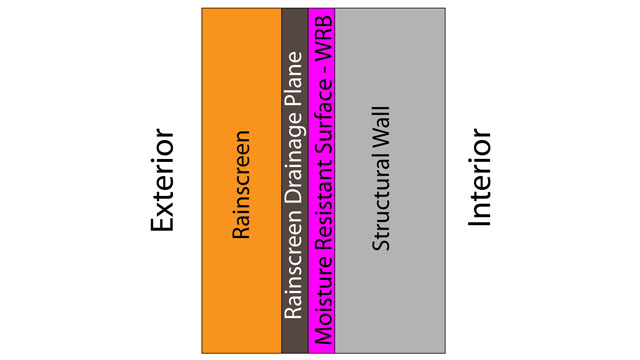

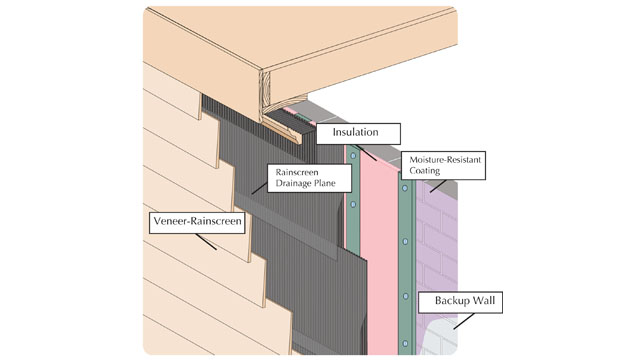

So, the hole/whole story is a little more complicated. As part of the process of moving forward, let’s take a look at an example of a typical exterior wall (exterior building envelope). Obviously, many types of wall systems exist, but let’s use this one (see Figure 2.) to simplify the discussion as much as possible.

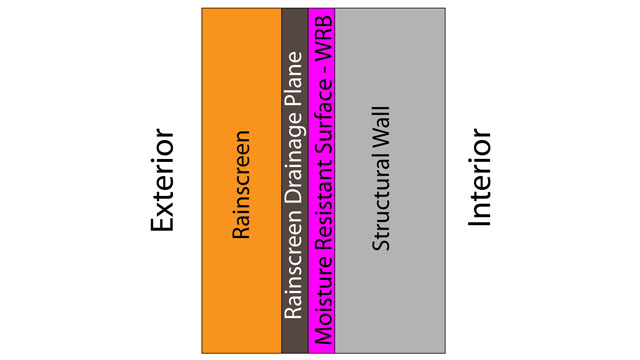

The next section, the rainscreen drainage plane, is the space from the backside of the rainscreen to the front surface of the moisture-resistant material. It can be either a wall design feature (such as a space) or a product.

The third section, the weather-resistant surface, can be a waterproofing product (usually a sprayed or rolled on chemical compound) or a weather-resistant material (two layers of construction paper or a building wrap). It also can be both.

The final section, the structural wall, can be composed of a variety of materials, including wood or steel studs, CMUs or poured concrete.

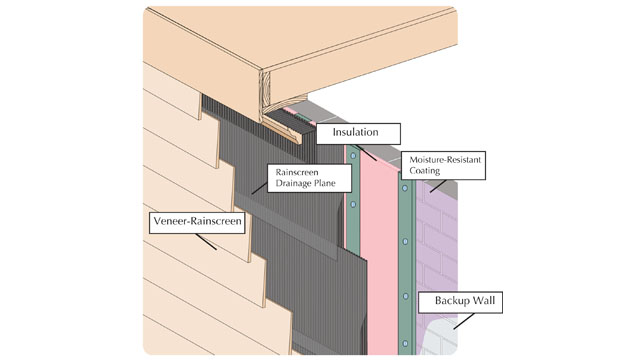

In most cases, a requirement for insulation exists. It comes in many forms and can be placed in various locations in this detail. It is an extremely important and complicated character in the hole/whole story, and must be included in the moisture-management equation. (See Figure 3.) All forms of insulation involve unique moisture-management issues beyond the scope of this article, However, they must be seriously examined when constructing a moisture-management plan for the rainscreen building envelope.

According to the HUD’s Path Project (www.pathnet.org), “Moisture, in all of its physical forms, is commonly regarded as the single-greatest threat to durability and the long-term performance of the housing stock. Excessive exposure to moisture is not only a common cause of significant damage to many types of building components and materials, it also can lead to unhealthy indoor living environments. A long list of serious, adverse effects can result from moisture problems in houses. There is wide agreement that successful management of moisture in its various forms is essential for houses (buildings) to be durable, safe and energy efficient.”

In its 2004 report, the Path Projected listed the following outcomes of uncontrolled moisture in the building envelope:

It’s a nice sunny day, so a rider decides to go for a motorcycle ride. Being an experienced motorcyclist, he always has raingear in his saddlebags, because it’s summer, and anything is possible. As he moves through the countryside, he notices that the sky is darkening, and a storm is imminent, so he pulls over and puts on his rain suit.

In a matter of minutes, the rain starts. It’s light at first but soon becomes heavy, and it’s coupled with a driving wind. Rain is forced around the rider’s windshield and into his eyes, greatly limiting his ability to see the road. Water cascades off his helmet and runs down the back of his neck, soaking his shirt. The water on the highway flies upward, leaking into his boots through the seams and around the tongue. To make matters even worse, it’s a hot, humid day, so beads of condensation start to form on the inside of his rain suit, making for an increasingly miserable ride. Obviously, even though he thought he was prepared for rain, he hadn’t looked at all possibilities.

Even though he had a collection of items designed to keep him dry, he hadn’t fully thought through the outcome, and he hadn’t properly combined the items into a functioning system. If he had used goggles or a helmet with a visor, he could have seen the road better. If he had used the hood on his jacket and worn it under the helmet, he wouldn’t have gotten rain down his back. If he had used a rain jacket with vents, air could have moved around inside the system and reduced the condensation. Finally, had he worn rain boots with his rain pants lapped over the top of the boots and fastened snugly, he wouldn’t have gotten wet from the water spraying up from the road.

So what can be learned from this analogy about the importance of a system in solving the building envelope moisture management problem? Hopefully, it’s that simple solutions don’t always work. As much as the motorcycle rider would like to just throw on a waterproof jacket and waterproof pants and be off again, it just doesn’t work. It takes many products, put on in the right order and at the right time, to create a positive result. We need to look at how many factors are in play, and then employ several moisture-management solutions as part of a system to solve the problem.

This brings us back to our hole/whole story concept. “Merriam-Websters” defines holistic as “relating to or concerned with wholes or with complete systems, rather than with the analysis of, treatment of, or dissection into parts.” Knowing how each product used in the construction of the building reacts with the rest of the products is critical. Is it compatible with the rest of the system, or does it create unintended consequences? Have the parties designing, specifying and installing the products looked at all the possible outcomes of the each procedure, and each product, with the rest of the system? That’s the “whole” part of the concept.

The “hole” part of the concept refers to the importance of drainage in an effective moisture-management solution in the rainscreen building envelope. The normal interpretation of a hole in a building envelope is negative. However, all building envelopes leak. Moisture can enter from the outside in multiple ways, including wind-driven rain and cracks in the veneer. Moisture can enter from the inside in the form of condensation. So, if we know water is going to get in, how is it going to get out?

In many places, drainage of the exterior building envelope is a code requirement. Section 1403 Performance Requirements (“International Building Code 2009,” pp. 277-278) states: “1403.2 Weather Protection. Exterior walls shall provide the building with a weather-resistant exterior wall envelope. The exterior wall envelope shall include flashing, as described in Section 1405.4. The exterior wall envelope shall be designed and constructed in such a manner as to prevent the accumulation of water within the wall assembly by providing a water-resistive barrier behind the exterior veneer, as described in Section 1404.2, and a means for draining water that enters the assembly to the exterior.”

Subsection 9.27.2.3-1b of the “National Building Code of Canada 2005,” Vol. 1 states:

“The second plane (the drainage plane) of protection shall be designed and constructed to

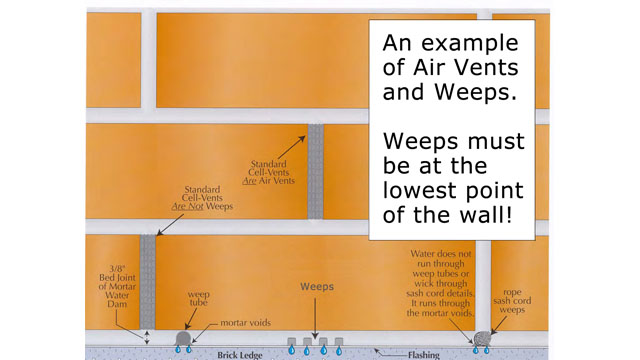

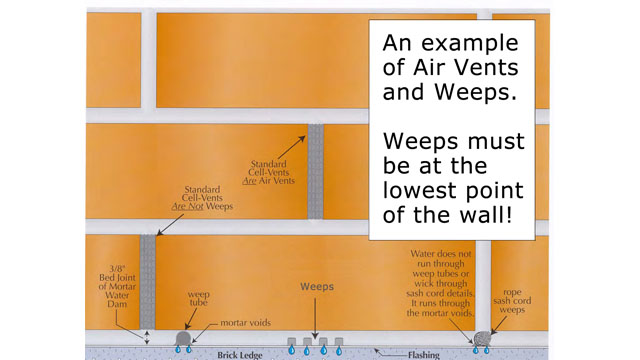

The holes referenced are weeps, but not just any weeps. Gone are the days of the “wicking” rope weep or the weep tube. If these old-style weeps worked at all, it was because some water leaked out of the moisture voids next to them and not through the weep itself. Many times, these antiquated weep devices weren’t even placed at the lowest point in the wall. An effective weep must be placed at the lowest point in the wall (the bed joint of mortar). Weeps also need to be placed frequently to be effective. The channeled weeps in Figure 6 are placed 10 inches on center.

During the last 20 to 30 years, we have experienced myriad moisture-related problems in the building envelope. The increased use of rainscreen technology by designers has seen more than its share. Many reasons for moisture problems in the rainscreen building envelope exist. Some of the most frequent issues include:

First, a space must exist from the backside of the rainscreen (veneer) to the face (exterior surface) of the WRB. (The minimum depth is still being debated, but should be at least 1/8-inch. In Canada, 10mm is required.) This space must be uninterrupted, predictable, constant and stable, and the materials used to create it should have low absorbency.

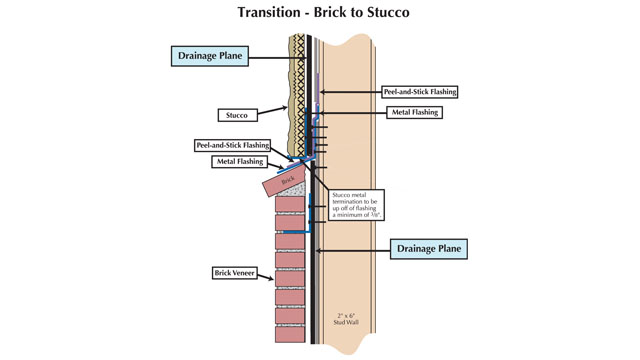

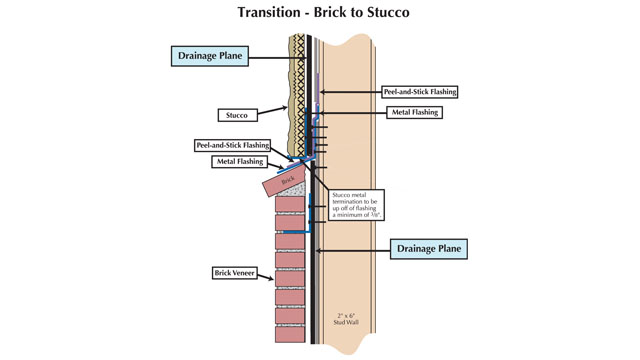

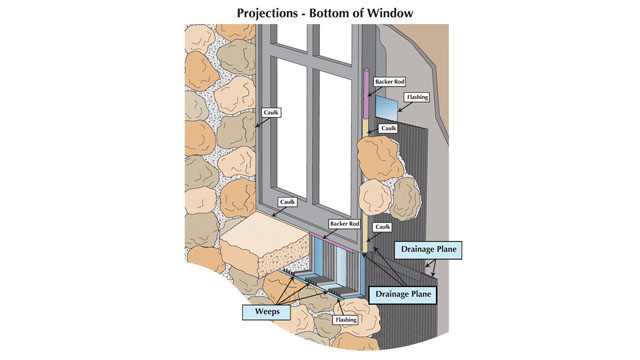

Second, we need to dump the water (weep holes) out of the rainscreen drainage plane at every possible opportunity. Water should be dumped at transition details (e.g. brick to stucco, siding to brick or stucco, etc.), projection details (e.g. windows at top, windows at bottom), and wall terminations (e.g. bottom of wall, top of wall). (See Figures 9, 10, 11.)

The final component is air-pressure control. A well-designed rainscreen drainage plane system helps maintain pressure equalization. It lessens the chance that high-pressure air, contaminated with moisture, will move from high-pressure to low-pressure, and deeper into the building envelope. And with venting at the top and bottom of the wall (see Figure 12), airflow may assist in drying the building envelope.

Lu Bu Wei, a Chinese philosopher wrote, “It follows, then, that all things work together…The Sage examines them in order to observe their similarities.”

In other words, looking for one simple solution to preventing moisture problems in something as complex as a modern building is unrealistic. Too many things come into play: materials used, the laws of physics, the people involved, location/climate, the many systems brought together in the building. To reach a true “waterproofing” result, we must work together as a team to create the right moisture management system. And that is the hole/whole story.

Drainable is sustainable

Why the best waterproofing system includes a drainage plane system

By Mark A. Johnson, John Koester

Stone veneer removal on home with entrapped moisture damage to rainscreen building envelope.

Most exterior surfaces of a vertical wall system do allow some moisture to penetrate more deeply into the exterior building envelope. Why do building professionals allow this? Don’t we have adequate waterproofing systems? Of course we know, and of course we do, but that isn’t the “hole/whole” story.The hole/whole story – the more complete story – is that some exterior building surfaces of the exterior building envelope are responsible for more than just moisture management. These responsibilities include aesthetics, structural support, signage support, mechanical support and protection (veneers acting as shields). In addition to all these responsibilities, they also have to manage moisture.

So, the hole/whole story is a little more complicated. As part of the process of moving forward, let’s take a look at an example of a typical exterior wall (exterior building envelope). Obviously, many types of wall systems exist, but let’s use this one (see Figure 2.) to simplify the discussion as much as possible.

Figure 2

Rainscreen components

The rainscreen is the most exterior surface of an exterior building envelope. It is the first surface that has the potential to change the exterior environment to satisfy a desired interior environment: wet to dry, hot to cool, cold to warm. It can be constructed of various materials, including brick, stone, stucco, steel, wood, glass, plastics and fabrics.The next section, the rainscreen drainage plane, is the space from the backside of the rainscreen to the front surface of the moisture-resistant material. It can be either a wall design feature (such as a space) or a product.

The third section, the weather-resistant surface, can be a waterproofing product (usually a sprayed or rolled on chemical compound) or a weather-resistant material (two layers of construction paper or a building wrap). It also can be both.

The final section, the structural wall, can be composed of a variety of materials, including wood or steel studs, CMUs or poured concrete.

In most cases, a requirement for insulation exists. It comes in many forms and can be placed in various locations in this detail. It is an extremely important and complicated character in the hole/whole story, and must be included in the moisture-management equation. (See Figure 3.) All forms of insulation involve unique moisture-management issues beyond the scope of this article, However, they must be seriously examined when constructing a moisture-management plan for the rainscreen building envelope.

Figure 3

Sustainable building and moisture management

Sustainable building isn’t possible without moisture management. For those forced to live or work in a building without it, life becomes a health and safety nightmare. These are bold, but totally supportable, statements.

View of rotted WRB, OSB and wood products, due to entrapped moisture.

According to the HUD’s Path Project (www.pathnet.org), “Moisture, in all of its physical forms, is commonly regarded as the single-greatest threat to durability and the long-term performance of the housing stock. Excessive exposure to moisture is not only a common cause of significant damage to many types of building components and materials, it also can lead to unhealthy indoor living environments. A long list of serious, adverse effects can result from moisture problems in houses. There is wide agreement that successful management of moisture in its various forms is essential for houses (buildings) to be durable, safe and energy efficient.”

In its 2004 report, the Path Projected listed the following outcomes of uncontrolled moisture in the building envelope:

- Decay of wood and corrosion of metals

- Infestation by termites and other destructive insects

- Negative impacts on indoor air quality

- Growth of mold, mildew and other biological contaminants

- Reduced building material strength

- Expansion/contraction damage to materials

- Reduced thermal resistance of wet insulation

- Premature failures of paints and coatings

- Damage to building contents

- Negative effects on building aesthetics.

Motorcyclists enjoying a ride

Motorcycles, rain suits and moisture management

To illustrate the importance of a coordinated system in moisture management, let’s use the analogy of a motorcyclist riding toward an approaching storm.It’s a nice sunny day, so a rider decides to go for a motorcycle ride. Being an experienced motorcyclist, he always has raingear in his saddlebags, because it’s summer, and anything is possible. As he moves through the countryside, he notices that the sky is darkening, and a storm is imminent, so he pulls over and puts on his rain suit.

In a matter of minutes, the rain starts. It’s light at first but soon becomes heavy, and it’s coupled with a driving wind. Rain is forced around the rider’s windshield and into his eyes, greatly limiting his ability to see the road. Water cascades off his helmet and runs down the back of his neck, soaking his shirt. The water on the highway flies upward, leaking into his boots through the seams and around the tongue. To make matters even worse, it’s a hot, humid day, so beads of condensation start to form on the inside of his rain suit, making for an increasingly miserable ride. Obviously, even though he thought he was prepared for rain, he hadn’t looked at all possibilities.

Even though he had a collection of items designed to keep him dry, he hadn’t fully thought through the outcome, and he hadn’t properly combined the items into a functioning system. If he had used goggles or a helmet with a visor, he could have seen the road better. If he had used the hood on his jacket and worn it under the helmet, he wouldn’t have gotten rain down his back. If he had used a rain jacket with vents, air could have moved around inside the system and reduced the condensation. Finally, had he worn rain boots with his rain pants lapped over the top of the boots and fastened snugly, he wouldn’t have gotten wet from the water spraying up from the road.

So what can be learned from this analogy about the importance of a system in solving the building envelope moisture management problem? Hopefully, it’s that simple solutions don’t always work. As much as the motorcycle rider would like to just throw on a waterproof jacket and waterproof pants and be off again, it just doesn’t work. It takes many products, put on in the right order and at the right time, to create a positive result. We need to look at how many factors are in play, and then employ several moisture-management solutions as part of a system to solve the problem.

The importance of holistic-systemic building

This same idea of a coordinated, multi-component solution can be applied to the people designing, specifying and constructing a building. Gone are the days when designers, specifiers and contractors could do their jobs successfully in a vacuum. Too many new products, processes and complex codes exist for the “Lone Ranger” approach to work. Everyone must collaborate and communicate if a sustainable, healthy building is the goal.This brings us back to our hole/whole story concept. “Merriam-Websters” defines holistic as “relating to or concerned with wholes or with complete systems, rather than with the analysis of, treatment of, or dissection into parts.” Knowing how each product used in the construction of the building reacts with the rest of the products is critical. Is it compatible with the rest of the system, or does it create unintended consequences? Have the parties designing, specifying and installing the products looked at all the possible outcomes of the each procedure, and each product, with the rest of the system? That’s the “whole” part of the concept.

The “hole” part of the concept refers to the importance of drainage in an effective moisture-management solution in the rainscreen building envelope. The normal interpretation of a hole in a building envelope is negative. However, all building envelopes leak. Moisture can enter from the outside in multiple ways, including wind-driven rain and cracks in the veneer. Moisture can enter from the inside in the form of condensation. So, if we know water is going to get in, how is it going to get out?

In many places, drainage of the exterior building envelope is a code requirement. Section 1403 Performance Requirements (“International Building Code 2009,” pp. 277-278) states: “1403.2 Weather Protection. Exterior walls shall provide the building with a weather-resistant exterior wall envelope. The exterior wall envelope shall include flashing, as described in Section 1405.4. The exterior wall envelope shall be designed and constructed in such a manner as to prevent the accumulation of water within the wall assembly by providing a water-resistive barrier behind the exterior veneer, as described in Section 1404.2, and a means for draining water that enters the assembly to the exterior.”

Figure 6

Subsection 9.27.2.3-1b of the “National Building Code of Canada 2005,” Vol. 1 states:

“The second plane (the drainage plane) of protection shall be designed and constructed to

- intercept all rain and snow that gets passed the first plane (the veneer) of protection and,

- effectively dissipate any rain or snow to the exterior.”

View of entrapped moisture damage to materials in a rainscreen building envelope with no drainage.

Real waterproofing involves real drainage

In his August 2010 article “Putting in Holes to Stop Leaks,” Brett Newkirk wrote, “A wise Canadian once said, ‘It is amazing how many leaks you can stop by putting holes in a building.’”The holes referenced are weeps, but not just any weeps. Gone are the days of the “wicking” rope weep or the weep tube. If these old-style weeps worked at all, it was because some water leaked out of the moisture voids next to them and not through the weep itself. Many times, these antiquated weep devices weren’t even placed at the lowest point in the wall. An effective weep must be placed at the lowest point in the wall (the bed joint of mortar). Weeps also need to be placed frequently to be effective. The channeled weeps in Figure 6 are placed 10 inches on center.

During the last 20 to 30 years, we have experienced myriad moisture-related problems in the building envelope. The increased use of rainscreen technology by designers has seen more than its share. Many reasons for moisture problems in the rainscreen building envelope exist. Some of the most frequent issues include:

- Tighter building envelopes increased mold and rot problem

- Many modern materials created unintended moisture barriers

- Increased insulation led to condensation problems.

Three key components

Rainscreen walls with a wide variety of veneers are sustainable, when combined with the right moisture-management system. This effective moisture-management system includes three key components.First, a space must exist from the backside of the rainscreen (veneer) to the face (exterior surface) of the WRB. (The minimum depth is still being debated, but should be at least 1/8-inch. In Canada, 10mm is required.) This space must be uninterrupted, predictable, constant and stable, and the materials used to create it should have low absorbency.

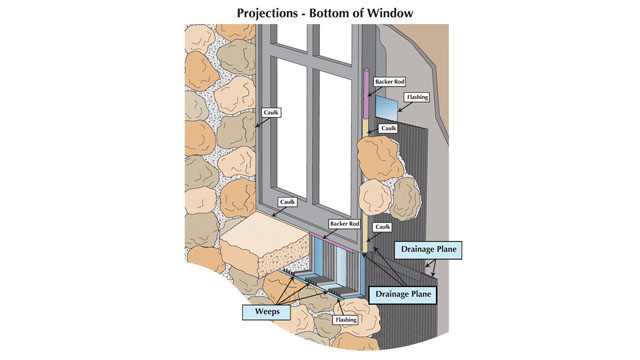

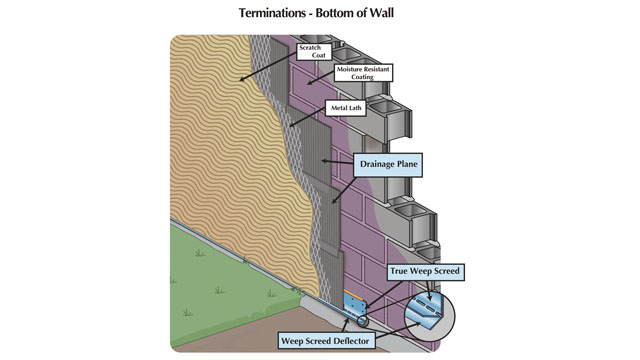

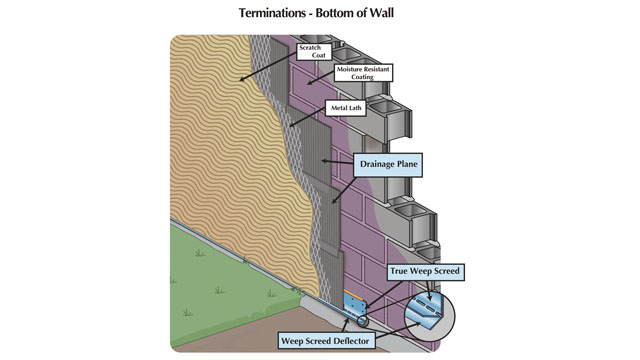

Second, we need to dump the water (weep holes) out of the rainscreen drainage plane at every possible opportunity. Water should be dumped at transition details (e.g. brick to stucco, siding to brick or stucco, etc.), projection details (e.g. windows at top, windows at bottom), and wall terminations (e.g. bottom of wall, top of wall). (See Figures 9, 10, 11.)

Figure 9

Figure 10

Figure 11

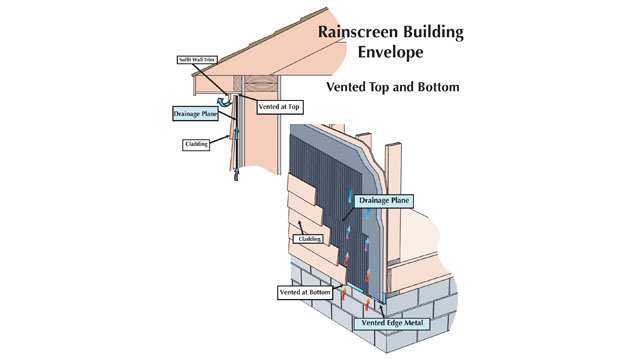

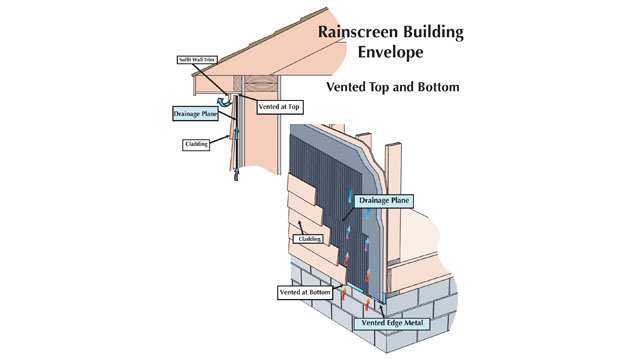

The final component is air-pressure control. A well-designed rainscreen drainage plane system helps maintain pressure equalization. It lessens the chance that high-pressure air, contaminated with moisture, will move from high-pressure to low-pressure, and deeper into the building envelope. And with venting at the top and bottom of the wall (see Figure 12), airflow may assist in drying the building envelope.

Figure 12

Lu Bu Wei, a Chinese philosopher wrote, “It follows, then, that all things work together…The Sage examines them in order to observe their similarities.”

View of weeps correctly placed at the lowest point in the wall.

In other words, looking for one simple solution to preventing moisture problems in something as complex as a modern building is unrealistic. Too many things come into play: materials used, the laws of physics, the people involved, location/climate, the many systems brought together in the building. To reach a true “waterproofing” result, we must work together as a team to create the right moisture management system. And that is the hole/whole story.

Originally published in Masonry magazine.

About the Authors

Mark A. Johnson is the media technologies manager for Masonry Technology Inc. He has a background in construction, education and communications technology.

John Koester is CEO Masonry Technology, Inc. He can be contacted at johnk@mtidry.com.