Origin, evolution, and design of masonry at New Jersey justice building

Case study

When we were designing the Maplewood Police & Court Building, we faced numerous challenges. This article describes three of them, and how we addressed them in the building’s masonry work.

Maplewood, New Jersey is a progressive western suburb of New York City with a long history of distinguished masonry public buildings. Most notable among these is its iconic Municipal Building, which has appeared in a number of motion pictures (image A). When the municipality selected us to design a replacement for its 75-year-old Police Headquarters, the decision as to what to clad it with was easy, given that history: brick it would be.

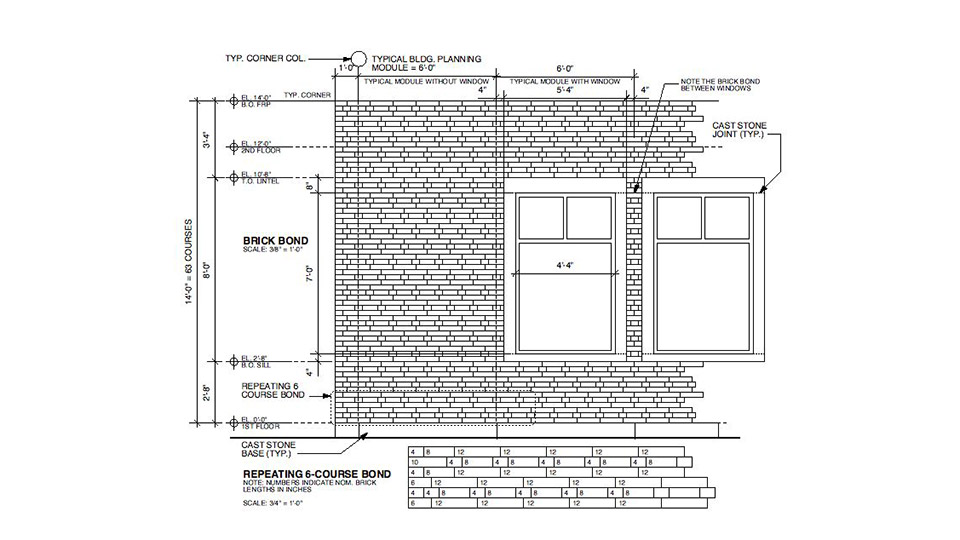

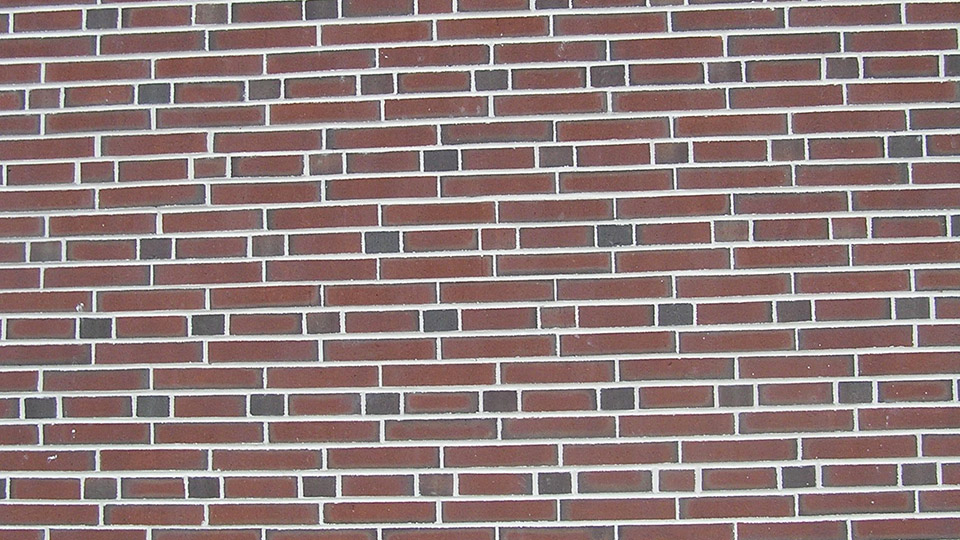

Not surprisingly, there was a bit of a learning curve for the masons as they started laying the building’s brick veneer. The contrast between the dark red brick and bright white mortar made workmanship especially critical. The masons rose to the occasion, and produced exceptional work (image C). However, it wasn’t until they had clad large enough areas of the facade to fill one’s view from a significant distance away, that it became apparent how visually dynamic the bond actually was. The strong contrast between the brick and the mortar, in combination with the contrasting sizes of the stretchers and headers and the alternating headers, animates the facade, especially in bright sunlight (image D). One senses a basketweave pattern, but it is all a visual illusion.

In the years leading up to the start of this project, Maplewood had established itself as a leader in environmental consciousness. The Mayor felt that new commercial buildings in town should be green and that the township should lead by example. As the Township’s first new public building in two generations, the Police Building thus presented the opportunity to manifest the community’s commitment to sustainable design and construction.

The goal became LEED certification. The Mayor and I identified an ideal south-facing site along the municipality’s main commercial avenue, backing up to a beautiful park. The building’s public spaces would enfront the street, and the Lobby would be flooded with daylight.

Although heating and cooling represent the largest uses of energy in buildings, lighting is not far behind. For that reason, we try to maximize the use of daylighting in our projects. It became obvious that, to fit the program on the relatively small site, the Police Building would need a full Basement. In addition to an indoor Firing Range and the Cellblock, it would contain the Locker and Shower Rooms for the sworn personnel and their Fitness Room. As the design evolved, the Fitness Room ended up directly under the building’s Main Lobby. I wondered: Was there a way to share the daylight from the Lobby with the Fitness Room below it?

I recalled having seen buildings from the early 20th century with glass block floors. A search on the internet turned up a manufacturer, Circle Redmont, that could make precast concrete panels incorporating glass block. Their technical staff confirmed the feasibility of our idea. When they heard that we were considering finishing the Lobby floor with terrazzo, they recommended that the glass blocks project above the surrounding concrete in the precast panels (image E), so that the terrazzo could be finished flush with the glass block in the finished construction (image F). The grinding of the terrazzo resulted in a “ground-glass” character at the glass block, maintaining some visual privacy between the upper and lower spaces. The net result was a Fitness Room that frequently gets enough light from above (image G) that it can be used with the lights off.

Among the distinguishing features of the Maplewood Municipal Building are the brick arches over its Palladian windows (image H). In the Police Building, we decided to use arches to frame the main pedestrian and vehicular entrances. For further inspiration, we studied the many public buildings of H.H. Richardson and his contemporaries in the late 1800’s.

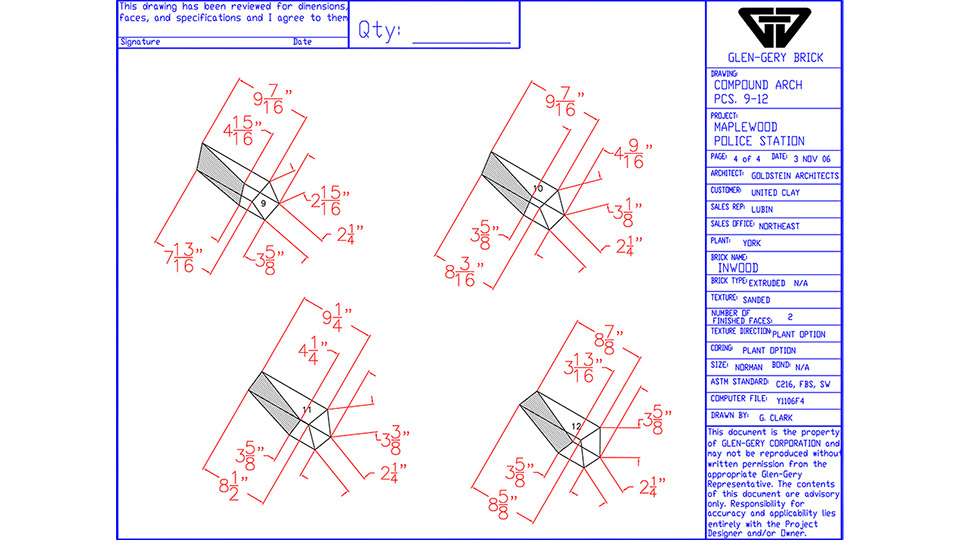

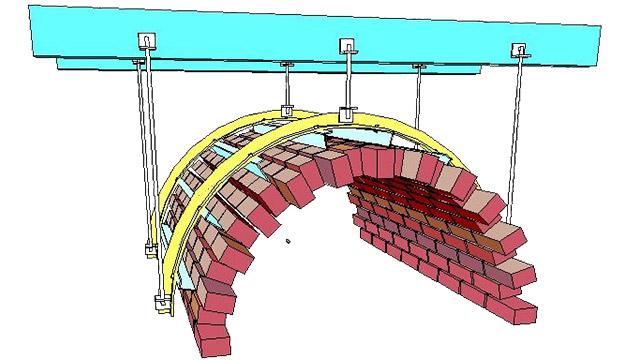

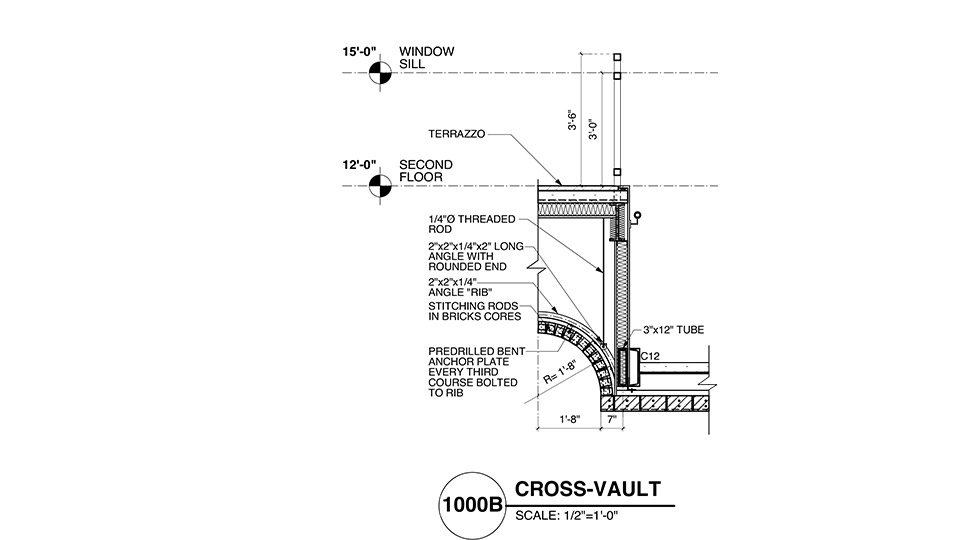

The building’s main entrance would be defined by a large brick vault, with the name of the building incised into the cast stone voussoirs of the arch at its outer face. To comply with today’s building codes, the Lobby would need at least two exits and they would have to be separated from one another. We placed these emergency exits in smaller cross-vaults at the sides of the arch. The curving intersections of the main vault with the cross-vaults required custom bricks. Each one was unique. It took several iterations for the brick manufacturer, Glen-Gery, to come up with shop drawings that accurately captured the geometric complexities (image I). The centering required to construct the vaults was quite substantial (image J). The completed vaults are quite dramatic (images K and L).

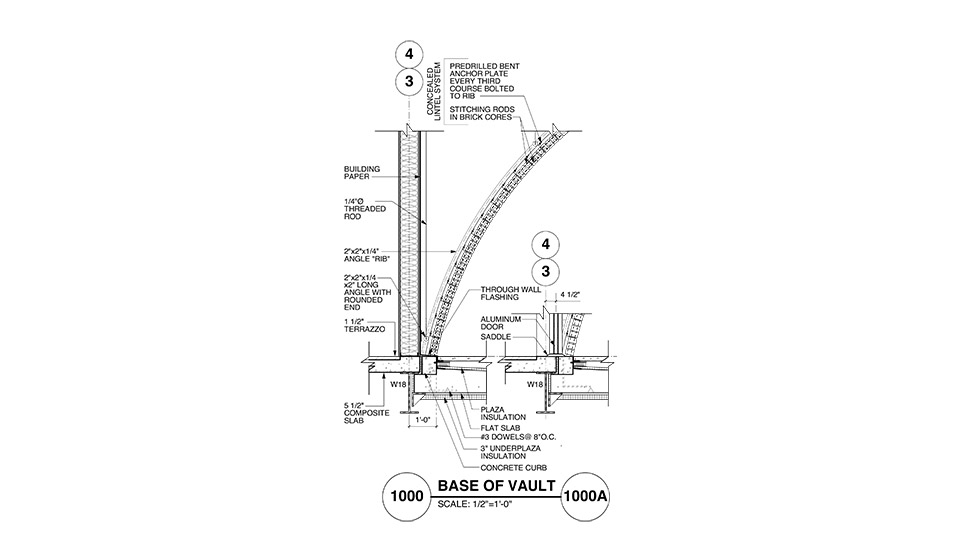

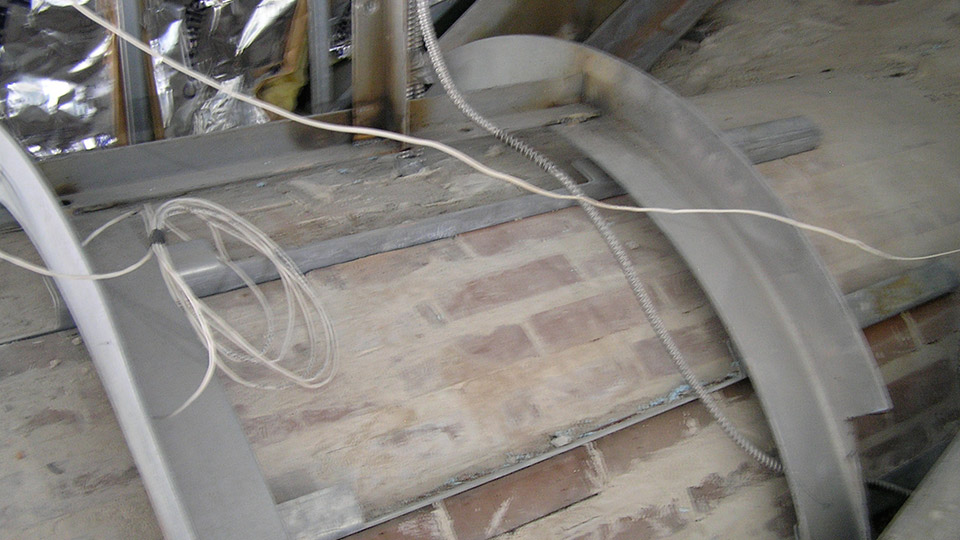

In its ideal form, an arch is a structural shape exclusively in compression. However, in an area, such as northern New Jersey, which has a history of moderate seismicity, conditions on the ground can cause stress reversals. To deal with such conditions, the vault had to be able to resist tension. This was achieved by using cored brick, and threading slender reinforcing rods — so-called “pencil” rods — through the cores. To prevent the vault from shifting with respect to the building’s overall structure, steel angles from Halfen were incorporated into the vault and were tied together with arched steel angles. These, in turn, were suspended from the building’s structural frame. It took a number of details to explain how this was to be achieved (images M, N, and O).

Until the space above the arch was closed up, this assembly and its many suspender rods had the appearance of a high-tech puppet (image P and Q). Once that space was enclosed, the complex engineering that made it all possible was hidden forever (image F).

To minimize uncontrolled air exchange between the inside and outside of the building (an important aspect of sustainable design), the building’s front entrance is a revolving door. We carried the round form of its enclosure out into the entrance plaza, in the pattern of joints in its custom precast pavers. The curtain wall which surrounds the front door was fabricated with an arched top, to fill the void under the vault (image R).

Overall, the Maplewood Police & Court Building illustrates the remarkable versatility of masonry construction and the rich design possibilities associated with its materials and the ways that they are installed.

About the Author

Eli Goldstein, AIA, PP, LEED AP, is a Managing Partner at The Goldstein Partnership.

© 2015 The Goldstein Partnership