An Introduction to Embedded Fasteners in Masonry

Understanding the embedded fastening options

When attaching structural and non-structural components to masonry, understanding the embedded fastening options along with their advantages, limitations and challenges is the first step to a successful connection. Where reliable performance is desired, the most common assurance that masonry fasteners will satisfy the demands of masonry design is provided through certification by well-established third-party evaluation agencies. This article describes various types of fasteners for masonry, notes specific installation and application considerations, and emphasizes the value of third-party evaluation reports issued by, e.g., ICC Evaluation Service LLC (ICC-ES).

Background

In addition to cast-in tie wires, veneers and other elements are connected with a variety of embedded fasteners, including power-actuated pins (nails), screws and anchors. Three major categories to which components are fastened are explored in this article:- Grout-filled CMU offers the highest load capacity of the three masonry types listed. Possible installation locations include the face of the masonry wall (including bed joints, webs and the center of face shell), the top of the wall (directly into grout), and the sides of the wall. Note: CMU head joints are generally not a reliable substrate for anchoring due to non-uniform buttering between adjacent units and the stress discontinuities between the mortar and adjacent blocks. Thus, fastening to head joints should generally be avoided, even if the head joints are fully buttered. One should ensure (via, e.g., ICC-ES Evaluation Service Reports) that the published loads for connectors are associated with the specified masonry design strength, f’m, being used. TMS 402-13/ACI 530-13/ASCE 5-13 §9.1.9.1 specifies that design must be considered with 1,500 psi masonry; therefore, many fastener manufacturers choose to develop product data for this minimum strength. Similarly, manufacturers often report data associated with Type N mortar to conservatively cover the range of mortar options in new construction.

- Hollow CMU attachments include fastening directly into the face shell of non-grouted CMU. When utilizing products that are installed through drilled holes in the face shell of hollow masonry, verify whether the installation instructions for the product being installed require rotation-only drilling, as hammer drilling tends to break out more of the back of the face shell, which the product may or may not be designed to accommodate. As with grout-filled CMU, it is important to ensure that published loads are associated with the specified masonry strength.

- Brick. Whether hollow or solid, as with CMU, the technical data for the fastener should again be associated with the brick type, compressive strength, and mortar.

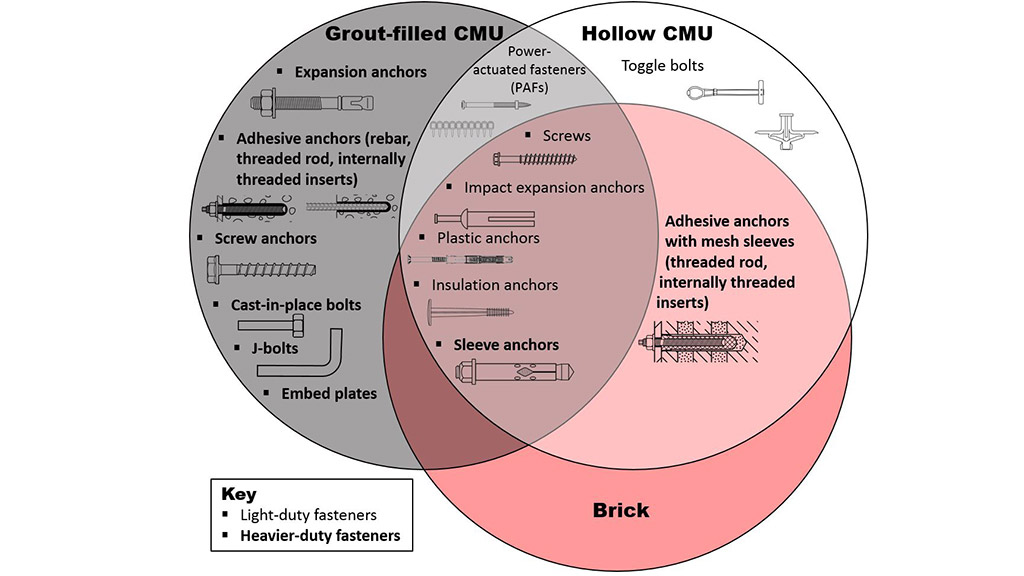

Light-Duty Embedded Masonry Fasteners

Typical applications for light-duty fasteners include metal and plastic sheets, insulation, electrical conduit and miscellaneous small fixtures. Because such connections generally require less load and require less installation effort than the anchorages described in the next section, installations of the connectors are typically to hollow masonry and within approximately 1/2 inch of the grouted portion of masonry.Power-actuated fasteners (PAFs), whether driven by powder, gas or electro-mechanical actuation, may generally be installed in hollow CMU, grout-filled CMU and brick. In addition to PAFs, self-drilling screws, insulation anchors, tamper-resistant impact expansion anchors, trigger anchors and plastic anchors provide specialized solutions for hollow CMU, grout-filled CMU and brick.

Heavier-Duty Embedded Masonry Fasteners

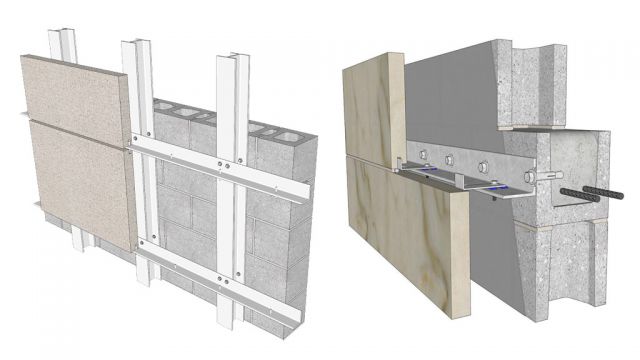

Typical applications requiring greater capacities for connections to masonry include cladding (pictured above), ledger angles, wood ledgers, sill plates, bearing plates, stone facades and external building equipment.Structural applications are generally associated with higher loads, often requiring greater embedment depths into grouted CMU or full utilization of the face shell capacity of hollow CMU. Figure 2 demonstrates typical applicable uses for heavier-duty connectors (generally, any of these connectors may also be used for light-duty applications). These applications are generally satisfied using anchor bolts, which can be either cast-in-place or post-installed, as explored in greater detail below.

Cast-in anchorages for connecting to the outside face of grouted CMU generally take the form of headed bolts, embedment plates and bent bars (J-bolts). To accomplish cast-in anchorages, planning and coordination are needed throughout wall fabrication and grout pouring. Cast-in installations to the face of masonry walls require holes to be drilled into the face shells of masonry, then for the bolts to be inserted from the inside of the masonry and tied either to reinforcement or to the inside of the masonry walls before pouring grout. Similarly, cast-in anchorages at the tops of walls must be set to the proper embedment and tied to the structure before pouring grout. Care must be taken during grout pours not to disturb these anchorages, which may result in misplacement and/or reduction in performance.

Post-installed anchorages to masonry, as with concrete, may be divided into adhesive and mechanical categories. Each type of masonry anchor provides a unique set of solutions for fastening to masonry elements.

Post-installed mechanical anchors include the following:

- Expansion anchors. The anchorage mechanism depends on expansion forces at the embedded end of the anchor, so it is important to see whether an anchor has been qualified for near-edge and top/side of wall installations. With the exception of sleeve anchors, expansion anchors are typically reserved in masonry for installations in grout-filled CMU.

- Sleeve anchors are a special subset of expansion anchors that function using a collapsing sleeve mechanism in hollow members, where they may be installed into face shells, as the collapsing sleeve will bear against the back end of the face shell. In solid members, sleeve anchors bear against the walls of the drilled hole to produce expansion forces and friction similar to the expansion anchors described above. Sleeve anchors should not be installed in the webs of hollow masonry,

- Screw anchors provide ease of installation. Screw anchors are especially useful for temporary installations, and in some cases are reusable. Because screw anchors require hardened threads to cut into concrete and masonry substrates, they are usually not intended for corrosive environments due to the potential of secondary hydrogen embrittlement.

Evaluation of Embedded Masonry Fasteners

Fastener manufacturers typically publish data on masonry fastener performance. Some companies publish data generated by third-party evaluation services according to established protocols, such as that provided by the International Code Council Evaluation Service (ICC-ES). In this case, one can be assured that the product has undergone significant testing and unbiased scrutiny. Through ICC-ES, manufacturers may obtain Evaluation Service Reports (ESRs) that demonstrate compliance with applicable Acceptance Criteria (AC) testing standards. The AC testing standards are developed to demonstrate compliance with model building codes, including TMS 402-13/ACI 530-13/ASCE 5-13.Power-actuated pins may be evaluated to ICC-ES AC70 Acceptance Criteria for Fasteners Power-Driven Into Concrete, Steel, and Masonry Elements, wherein products may be qualified for use in hollow masonry, grouted masonry and concrete. Testing involves determination of basic static tensile and shear capacity. While the reported data is put in simple tensile and shear capacity format, the scrutiny involved with an ICC-ES third-party review provides assurance that the product conforms to model code requirements.

The AC documents for post-installed anchor products prescribe testing protocols for anchors installed in masonry base materials in conjunction with ASTM E488 and ASTM E1512. A more detailed examination of anchor evaluation from the September 2011 issue of Masonry Magazine, “Verifying Codes and Standards Compliance,” describes the rigorous testing protocols that these types of anchors must undergo to demonstrate code compliance. In essence, anchors are subjected to thorough tensile and shear testing in the centers of face shells, bed joints and webs. In addition, adhesive anchors must undergo suitability tests to determine behavior under sustained load and elevated temperature. Optional tests include performance with angled loading, damp holes, freeze-thaw cycles, and seismic tension and shear.

Each of the AC documents has a corresponding document for anchoring products in concrete; if an anchor product has an ESR for concrete in addition to masonry, useful information (including, for example, hydrogen embrittlement resistance for screw anchors and resistance to alkalinity for adhesive anchors) can be gleaned with careful reading. The masonry AC documents and their concrete counterparts are listed below:

- AC01 Acceptance Criteria for Expansion Anchors in Masonry Elements (with equivalent concrete testing standard AC193).

- AC58 Acceptance Criteria for Adhesive Anchors in Masonry Elements (with equivalent concrete testing standard AC308).

- AC106 Acceptance Criteria for Predrilled Fasteners (Screw Anchors) in Masonry (with equivalent concrete testing standard AC193).

Having reviewed the options for fastening to masonry and the options for third-party data, the next step is design. A future article will focus on the design of fasteners to masonry in accordance with TMS 402-13/ACI 530-13/ASCE 5-13 code requirements, and how test data published in accordance with third-party evaluation reports may be used in conjunction with the code requirements.

About the Author

Kenton McBride is a Codes and Approvals Engineer at Hilti. He received his Ph.D. from the University of Florida, where he conducted his research on anchorage to concrete.

Acknowledgments: Peter Anderson, P.E., Jesse Gonzalez, Chenkai Li, and Jennifer Ray, P.E. of Hilti generously contributed background information for this article.