There is no real substitute for good masonry construction.

November 9, 2016 7:00 AM CST

However, wall systems of brick masonry units and mortar joints can ― and sometimes do — allow water penetration. This normally occurs at the mortar-to-unit interface, not through the brick itself. Invariably, water penetration is the result of water passage through holes in mortar joints, unfilled joints, or separations due to insufficient bond between the mortar and brick units.

A 4-inch-thick masonry wall built from the best materials and with the best workmanship cannot be depended upon to completely resist water penetration caused by wind-driven rains. For this reason, masonry wall systems should be designed and built to accommodate some amount of water penetration through the single wythe of brick without penetrating into the interior building envelope.

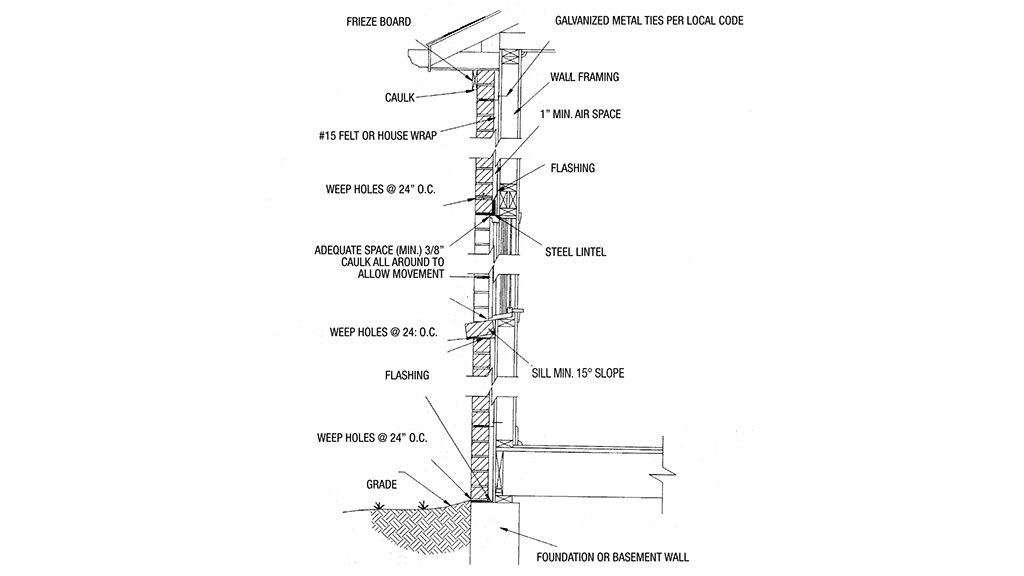

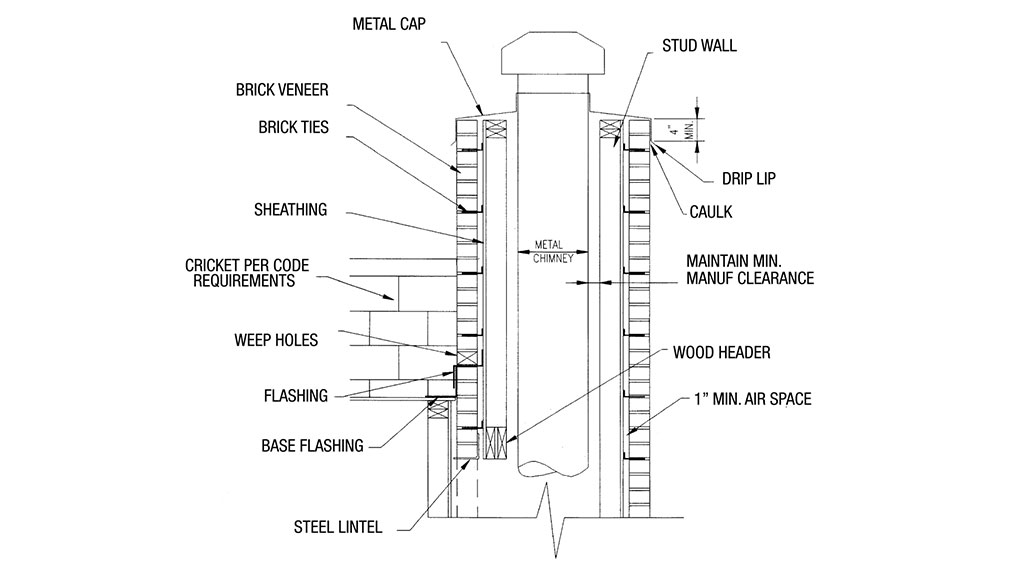

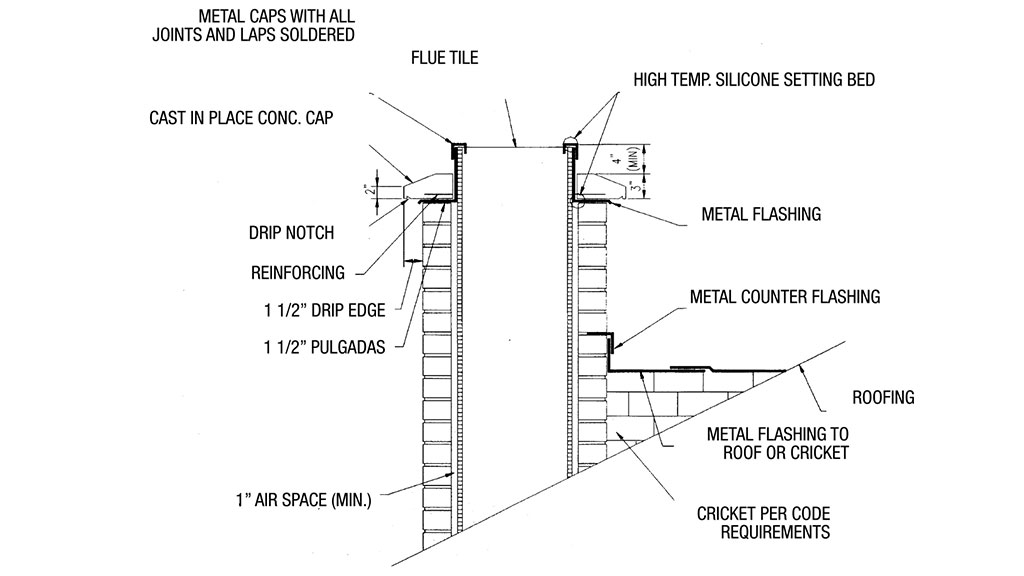

These drainage system requirements are not just brick industry recommendations. Flashing, weep holes and an air space are building code requirements.

The current building code for residential construction is the 2015 International Building Code (IBC). The IBC requires that masonry veneer systems include a 1-inch air space, flashing, and weep holes spaced at a maximum 33-inch O-C spacing. The IBC also requires crickets for chimneys greater than 30 inches wide.

While a large percentage of leaky wall problems is due to missing or inadequate drainage walls, other factors can cause or contribute to water penetration. Joint selection and workmanship are two potential factors. Mortar must be properly proportioned and mixed, and joints must be filled completely and properly tooled for weather-resistant construction.

Tooling is important for two reasons. Tooling helps compact and compress mortar, ensuring that the joints are completely filled. Tooling also compresses and smooths the mortar and cement at the joint surface, which results in a harder and more water-resistant finish. “Tooling” masonry joints with broomsticks, with the threaded portion of anchor bolts, or with wire brushes does not achieve the same results as tooling with proper joint finishing tools ― and actually does more harm than good. Tooling of joints must be done only after the mortar has achieved the proper set or plasticity. Many masons refer to this proper set as “thumbnail hard.”

Proper construction practices, including the preparation of materials and good workmanship, are factors that affect the bonding properties of the mortar to the brick units — and hence the weather resistance of a wall. Initial mortar selection should be based on the IRA (initial rate of absorption) or suction of the brick units. Mortar used with high-suction brick units should have adequate water-retention capacity. This capacity can be increased by the addition of lime or by increasing the mix time, which increases air content in the mortar. Brick units which have an IRA of 30 grams per minute may also require pre-wetting of the brick units. All of these factors can change in the field as the job proceeds, depending on site conditions and weather, and this may require adjustments to the mortar mix or the need to pre-wet. These adjustments cannot be pre-determined or written in a project specification. These are jobsite decisions that require the judgment of an experienced mason.

Selection of a well-graded masonry sand is also important. Coarse sands tend to produce a grainy, textured mortar, which has poor workability, bond strength and water resistance.

Architectural details are also important factors in weather-resistant construction. These details include:

The determination of a repair procedure can be complicated, however, because there may be several factors causing the issue. Since leaky wall repairs can involve considerable expense, a good deal of care should be taken, and perhaps an engineer be consulted, before making any recommendations to a customer. It should also be understood that leaky wall repair recommendations may be “trial and error” methods.

Some potential repair procedures include:

Leaky Walls in Brick Buildings

Proper residential masonry wall construction is required for meeting the 2015 International Building Code

Causes of Leaky Masonry Walls

While bricks do absorb water, it is virtually impossible for wind-driven rain to be forced completely through a brick body. During the brick manufacturing process, high kiln temperatures fuse raw materials into a solid, water-resistant mass. Because of this, individual bricks do not leak.However, wall systems of brick masonry units and mortar joints can ― and sometimes do — allow water penetration. This normally occurs at the mortar-to-unit interface, not through the brick itself. Invariably, water penetration is the result of water passage through holes in mortar joints, unfilled joints, or separations due to insufficient bond between the mortar and brick units.

A 4-inch-thick masonry wall built from the best materials and with the best workmanship cannot be depended upon to completely resist water penetration caused by wind-driven rains. For this reason, masonry wall systems should be designed and built to accommodate some amount of water penetration through the single wythe of brick without penetrating into the interior building envelope.

Brick Wall Design Systems for Weather-Resistant Construction

Two types of brick wall design systems are typically used for weather-resistant construction: a drainage-type wall or a barrier-type wall. The brick veneer wall system used on most residential projects is the drainage-type wall system. A drainage-type wall requires an unobstructed air space, properly installed flashing, and adequately spaced and open weep holes to conduct to the outside any water which has penetrated the exterior of the masonry.These drainage system requirements are not just brick industry recommendations. Flashing, weep holes and an air space are building code requirements.

The current building code for residential construction is the 2015 International Building Code (IBC). The IBC requires that masonry veneer systems include a 1-inch air space, flashing, and weep holes spaced at a maximum 33-inch O-C spacing. The IBC also requires crickets for chimneys greater than 30 inches wide.

While a large percentage of leaky wall problems is due to missing or inadequate drainage walls, other factors can cause or contribute to water penetration. Joint selection and workmanship are two potential factors. Mortar must be properly proportioned and mixed, and joints must be filled completely and properly tooled for weather-resistant construction.

Tooling is important for two reasons. Tooling helps compact and compress mortar, ensuring that the joints are completely filled. Tooling also compresses and smooths the mortar and cement at the joint surface, which results in a harder and more water-resistant finish. “Tooling” masonry joints with broomsticks, with the threaded portion of anchor bolts, or with wire brushes does not achieve the same results as tooling with proper joint finishing tools ― and actually does more harm than good. Tooling of joints must be done only after the mortar has achieved the proper set or plasticity. Many masons refer to this proper set as “thumbnail hard.”

Proper construction practices, including the preparation of materials and good workmanship, are factors that affect the bonding properties of the mortar to the brick units — and hence the weather resistance of a wall. Initial mortar selection should be based on the IRA (initial rate of absorption) or suction of the brick units. Mortar used with high-suction brick units should have adequate water-retention capacity. This capacity can be increased by the addition of lime or by increasing the mix time, which increases air content in the mortar. Brick units which have an IRA of 30 grams per minute may also require pre-wetting of the brick units. All of these factors can change in the field as the job proceeds, depending on site conditions and weather, and this may require adjustments to the mortar mix or the need to pre-wet. These adjustments cannot be pre-determined or written in a project specification. These are jobsite decisions that require the judgment of an experienced mason.

Selection of a well-graded masonry sand is also important. Coarse sands tend to produce a grainy, textured mortar, which has poor workability, bond strength and water resistance.

Architectural details are also important factors in weather-resistant construction. These details include:

- Properly constructed chimney cap with a drip edge.

- Roof crickets when required.

- Flashing specified and installed at base of walls, and above and below all openings.

- Adequate slope on window sills.

- Adequate frieze board coverage or caulking (consider that a wind-driven rain can be driven vertically upward approximately 1 inch for each 10-mph increment in wind speed).

- Adequate slope on porches, driveways and surrounding ground areas.

- Properly installed gutters and down spouts.

- Caulking around door and window openings.

Possible Fixes for Leaky Walls in Brick Buildings

Though there is no real substitute for good masonry construction, as long as critical drainage wall elements (flashing, weep holes and air space) installed during the initial construction of the building, leaky wall problems can often be repaired. Repairs can be as simple as applying a bead of caulk, or as major as removal and replacement of brick.The determination of a repair procedure can be complicated, however, because there may be several factors causing the issue. Since leaky wall repairs can involve considerable expense, a good deal of care should be taken, and perhaps an engineer be consulted, before making any recommendations to a customer. It should also be understood that leaky wall repair recommendations may be “trial and error” methods.

Some potential repair procedures include:

- Caulking frieze boards or chimney cap skirts.

- Selective tuck-pointing.

- Application of mortar bevel to corbel details.

- Application of a water repellent.

Note: The application of a good-quality water repellent can sometimes be effective as a repair for leaky wall problems, depending on the extent and cause of the problem. Water repellents will not fill holes and gaps in mortar joints, but some materials do have some crack-bridging capability for very fine mortar-to-brick separations. Water repellents are not a permanent repair and will require re-application. Siloxane-based repellents can have a life expectancy of more than 10 years. It is a good idea to consult with the material manufacturer to determine if application of a repellent is recommended and to determine which material to apply. - Replace chimney caps.

- Commercial waterproofing installations.

Note: Commercial waterproofing systems can be installed from the inside of the building. These applications may be effective when water can be localized to a single point, such as above a basement foundation wall. Before an application of this type is considered, it must be determined that water is not causing damage at elevations above the foundation wall. - Removal of brick for flashing replacement.

- Brick removal and replacement.

Note: This is a last resort but is sometimes the only effective solution for a water penetration problem.

Additional Information on Water Repellents

Certain general conditions should be met before applying a breathable siloxane-based water repellent to masonry walls:- Appearance of the walls must be acceptable before application. It will be difficult or impossible to remove dirt, stains or efflorescence after treatment.

- If tuck-pointing is required, it must be done before the water repellent is applied. Tuck-pointing mortar will not bond properly to a treated wall.

- The masonry must be dry.

- Do not use surface-forming or acrylic-based sealers on exterior masonry walls.

Note: The application of an acrylic sealer can actually do more harm than good when applied to an exterior masonry wall. Acrylic sealers can trap moisture inside a brick wall, which can cause fogging or, what is worse, spalling of the brick during a freeze-thaw cycle. Acrylic sealers can also cause a water penetration problem to worsen by what is sometimes called the funnel effect. Acrylic sealers are surface-forming and can create small ledges or lips on the edges of the brick units, which act to actually channel more water into the wall. - The application of a water repellent may cause a slight change in appearance to the masonry wall. Treated walls will also appear different or may “bead up” when wet. To ensure satisfaction with appearance, a test application should be made in an inconspicuous area.

- The application of any water repellent will not be effective if applied over poor masonry work. Mortar joints need to be filled and properly tooled. A water repellent will not bridge holes or fill gaps in mortar joints.

Originally published in Masonry magazine.

About the Author

Jim Bryja P.E., S.E. is the Manager of Engineering Services at General Shale.