Dealing with Codes and Standards is typically no fun, and keeping up with the changes can be a grind. But in the last few years, there have been a number of changes made to masonry codes and standards that Contractors (and Designers!) need to know about. They can also use them to help make masonry more cost competitive, easier to construct, and in a few cases, get us out of some tough binds.

and keeping up with the changes can be a grind. But in the last few years, there have been a number of changes made to masonry codes and standards that Contractors (and Designers!) need to know about. They can also use them to help make masonry more cost competitive, easier to construct, and in a few cases, get us out of some tough binds.

Changes to Codes and Standards seem like a continual thing, but fortunately for mason contractors, most of these changes affect how the units are manufactured, or more frequently, how masonry is designed. Since those changes don’t affect how masonry is constructed, we’ll not touch on those now as they are well documented in other sources targeted towards the design team (Bennett et al, 2017; Bennett et al, 2017; Throop et al, 2014; Samblanet (2015)). What we hope to do here is to highlight a few changes that contractors, and yes designers, should be aware of, and which may help with things going more smoothly on our masonry projects.

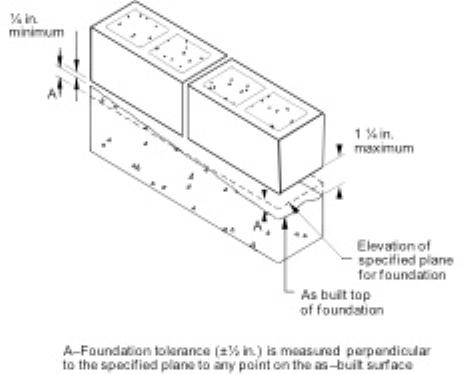

As many know, masonry special inspection is becoming more prevalent – sadly becoming more commonplace as a result of damage to poorly constructed buildings after severe events. And while these authors support special inspection, they also want inspectors to focus on the key things that can truly impact the strength and integrity of the masonry. Unfortunately, a few inspectors look for the minutia, and that can slow the project down. One such example, that many never really considered, is the initial bed joint between the first course of the masonry and the foundation below. Early Codes and Standards required this initial bed joint to be no less than ¼ in. and no more than ¾ in. (or 1 in. in some older Codes) For masonry, meeting this requirement wouldn’t be hard IF the foundation were built to reasonable tolerances. However, there is a “disconnect” in requirements between what masonry needs, and how concrete foundations are constructed: that is concrete footings can have a much greater tolerance and yet still comply with concrete standards. So, what is a mason to do? Well often in the past, we never even worried about this, and made the bed joint what it needed to be so that the first course of units was level and at the correct elevation so work could proceed more precisely afterwards. But some inspectors have cited this, and in a few rare cases, it has been a major issue. But by all rights the issue should be addressed before the mason steps on the job. The tolerances of the foundation should have been coordinated to ensure they are adequate for the masonry above. But we know how that goes…

So again, what to do? One ugly and expensive option is to scarify the surface of the concrete. But who will pay for that? And what happens if that lowers the grade so we don’t meet our elevations? Things get messy quickly, and people start pointing fingers. None of it is any fun. But what is the fundamental issue here anyway? Why does it matter if the initial bed joint is thicker?

The answer is pretty obvious when you think about it. The thicker a mortar joint is, the more it is exposed to drying air, and the more likely it is to crack. Being exposed to more “drying” air, also weakens the mortar. But more importantly, as the mortar gets taller and thinner, it’s strength in resisting compressive loads goes down. So an initial bed joint of say 2 in., can resist much less load than a 3/8 in. joint of the same “strength” due to this “height to thickness” affect. The question is, does that lower strength matter? And that is a hard question to answer, and it will vary based on the type of building you are working on (multistory loadbearing, versus a small retail building). The Code must provide safety, and is thus based on the worst-case scenario. But in hearing of the issue, and the problems it was causing, the Code Committee (TMS 402/602) considered this issue. Based on testing performed for the Concrete Masonry Association of California and Nevada and the Masonry Institute of America, it was found that if the bottom course of masonry is grouted, the mortar joint is “supported” somewhat by the grout, and load is shared with the grout. Based on that research, the 2013 TMS 602 was revised to allow the initial bed joint to be up to 1 ¼ in. thick when that initial bed joint is grouted (Figure 1). While it may not take care of every case where foundations are grossly out of tolerance, it does provide some relief.

Figure 1: Reprint of TMS 402-16 Figure SC-9 showing permitted initial bed joint thickness for solid grouted walls on a foundation

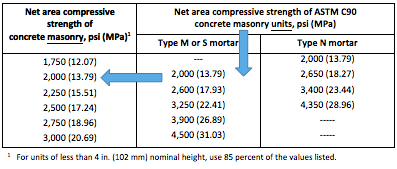

Another change that may perhaps get some out of some trouble on current projects, while potentially making concrete masonry more competitive, is an increase in two areas to the strength of concrete masonry. First ASTM C90 was revised to increase the strength of concrete masonry units (CMU) from 1900 psi to 2000 psi. By itself, this change is not significant, though it does show the commitment of the concrete masonry industry to provide stronger units. Perhaps more importantly however, was a recalibration of something called “the unit strength method” in TMS 602-13 of concrete masonry “assemblage” strengths. Some background is needed on this. Designers need a realistic strength of masonry to perform their basic calculations. Based on that strength, we determine whether a wall must be reinforced, if so, how much reinforcing is needed, how thick the wall must be, where the reinforcing is to be placed, and a number of other things that we then specify in the project documents. We “assume” strength based on the units intended, and the mortar we want used. In the past, we often used an f’m value (the specified strength of the masonry assemblage) of 1500 psi for normal, bare bones, nothing special concrete masonry units when laid with type S mortar. The mason then had to confirm that the strengths of the materials used exceeded this f’m using one or more methods that included the unit strength method or prism testing. For many years, we recognized that this assumed strength of 1,500 psi was conservative. With the increase in CMU strength in ASTM C90, the Code Committee (TMS 402/602) decided to re-examine the unit strength method. The result was a major change to the unit strength table in the 2013 TMS 602 that increased the strength of “normal” (ASTM C90 compliant) CMU laid with Type S mortar to 2,000 psi (Table 1). This increase means that designers can “do more” with concrete masonry, making it more competitive. From a contractor’s perspective, they should also be aware of this because current plans and specifications are likely based on the former unit strength method. Now with stronger units and the new unit strength method, meeting higher f’m values specific on some jobs is easier, perhaps without the added expense of prism testing.

Table 1: Reprint of TMS 602-16 Table 2 — Compressive strength of masonry based on the compressive strength of concrete masonry units and type of mortar used in construction

These, along with the permission to use self-consolidating grout (SCG) and grout demonstration panels show enhancements in the standards to address contractor concerns while recognizing new products and construction techniques.

More recently, the 2016 TMS 402/602 enhanced the Code and Specification in a number of ways that could also positively impact future masonry projects:

- Despite what many say or believe, the Code does not always make things worse. A key example of that is that TMS 402-16 relaxed anchor bolt requirements, providing greater capacity for anchors loaded with both shear and tension. This was coupled with a change to increase the crushing capacity of masonry surrounding anchor bolts. And outside masonry codes, the loading standard (ASCE 7-16) was also revised to reduce the required loads that anchor bolts must be designed to resist. All of these changes could mean a reduction in the number of anchor bolts required in the future.

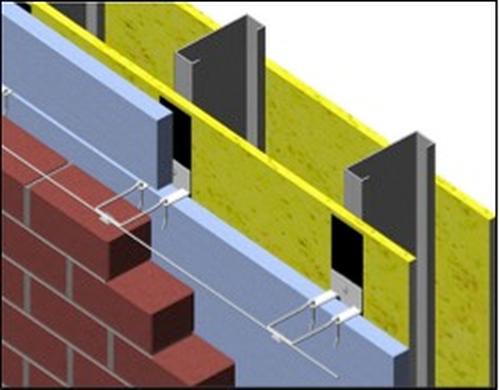

- Another change in TMS 402 related to the increase in permitted “cavity” between anchored veneer and the backing (Figure 2). TMS 402-13 and earlier standards permitted a cavity space of 4 ½ which was intended for 1/2 in. of sheathing, 2 inches of insulation and a 2 in. air space. The first enhancement that was considered was changing 4 ½in. to 4 5/8 in. since increasingly, 5/8in. sheathing is used over wood and steel stud backings. Additional changes were considered to increase the cavity even more to address ever-increasing energy code requirements – which in some areas is being met by increased insulation of 3 or even 4 inches. While TMS 402-13 and earlier standards do not prohibit larger cavities if “designed”, many were hoping the “prescriptive” requirements in Chapter 12 of TMS 402 could be expanded to allow larger cavities. The Code Committee approved expanding the prescriptive anchored veneer requirements to 6 5/8 in. in some cases. More robust anchors are required for the increased cavity width, including 1/4 in. diameter barrel anchors and plate and prong anchors with minimum thickness and dimensions.

Figure 2: Rendering of basic anchored veneer system with steel studs as the back-up system to illustrate sheathing, insulations and cavity

- TMS 602-16 now allows cast stone conforming to ASTM C1364 and manufactured stone conforming to ASTM C1670 to be used for appropriate veneer applications.

- TMS 602-16 Inspection and verification tables were consolidated and the result is easier to follow for inspectors, contractors, and designers.

- While not requiring masonry testing, TMS 602 was changed to say that if testing is required, only qualified testing technicians are permitted to conduct the tests. One would have hoped that such a requirement would not be needed, but in some areas of the country it is sadly common that masonry tests are being performed by technicians not familiar with masonry, nor masonry tests. The result is sometimes poorly executed tests, leading to erroneous results that can slow down or even stop masonry projects. This doesn’t help anyone. So if masonry testing is to be performed, it should be conducted by someone familiar with masonry and those specific tests. Commentary was added to note that those certified as Masonry Testing Field (MFTT) or Laboratory (MLTT) Technicians by the American Concrete Institute (ACI) are qualified to help contractors and managers know one method to confirm qualifications.

- Hoping to aide users, the TMS 402/602-16 Committee converted some requirements that were quite “wordy” to easier to follow “tables” and “figures”.

- And while it may be lost on the casual user, the TMS 402/602-16 Committee worked very hard to tighten up language and terms to reduce ambiguity, and to be more consistent. While such changes may not be needed by the experienced designer or contractor, they help make provisions clearer for those new to masonry. As a result of this, the 2016 Code and Specification has slightly fewer pages than the 2013 Code and Specification.

Certainly the above does not embrace all the changes to masonry codes and standards, but hopefully it highlights a number of changes on things that contractors and designers should know about, and in some cases, use to assist them on future masonry projects.

As a final thought, The Masonry Society and other standards writing organizations are always seeking input from contractors and others using the standards we produce. Contractors that are members of TMS assist in ensuring these standards are reasonable, yet safe. However, additional contractor input is always needed, and we encourage participation to ensure your views, opinions, and ideas are considered. For additional information, visit our website at www.masonrysociety.org.

1 Executive Director, The Masonry Society, psamblanet@masonrysociety.org

2 Professor, University of Tennessee, Department of Civil and Environmental Engineering, rmbennett@utk.edu

REFERENCES

Bennett et al, 2017: Bennett, R.M., “TMS 402/602-16 Changes”, TMS Responds, The Masonry Society, 2017.

Bennett et al, 2017: Bennett, R.M. , Pierson, D.L. , Dalrymple, G.A. and Samblanet, P.J., “The 2016 TMS 402-602 Code Requirements & Specification: What to Expect and Why”, 13th Canadian Masonry Symposium, Halifax, NS, CANADA, 2017.

Throop et al, 2014: Diane B. Throop, Richard M. Bennett, Gerald Dalrymple, and Phillip Samblanet, “The 2013 MSJC Code and Specification – What to Expect and Why”, ASTM Symposium on Masonry, STP 1577, ASTM, 2014 .

Samblanet (2015): 2015 IBC and Referenced Standards”, TMS Responds, Vol. 13, No. 1, The Masonry Society, 2015.