Advanced Workflows for BIM-M

By Ryan Page

When it comes to Building Information Management for Masonry (BIM-M), the upfront benefits that provide a return on investment have been documented well enough. Once adopting the technology it is relatively straightforward to produce models for current and upcoming projects that provide value to your company. This is a great first step. You now have a virtual representation of the project, can identify its constructability issues, obtain accurate quantities, and maybe even produce a few drawings. Now that you can accomplish the immediate goals that drove you to adopt BIM-M there is going to come to a point where you begin to postulate the next steps.

When we think about the term "Advanced Workflows", the first image that usually comes to mind is more complex tools or processes. Although this is not entirely untrue, the reality is more in line with advancing your current work process forward to leverage more out of what you can already accomplish. Yes, there is always the possibility of expanding your skillset with new tools but at the end of the day, in any BIM platform, how you use your model and the information contained with it is what will set you apart from the rest.

To put a finer point on it, utilizing "Advanced Workflows" is to move your business or process forward to provide more value than it already does. There is a multitude of ways to achieve this and it will not always be the same for every business, even for those like yourselves who focus on BIM-M. All we need to do is identify areas in which we can accomplish this. There are some main areas such as model management and field use, but there are other areas as well where companies can expand their modeling efforts.

One of the main cornerstones in advancing our BIM-M workflows is going to be how we manage our models. How we approach this will trickle down throughout the rest of our processes and projects. Most BIM-M platforms provide basic, out of the box settings and tools that help speed up the creation of models. In addition to this, platforms such as Tekla Structures allow for customization through saving of settings for tools, part creation, drawings, reporting, and so on. The ability to do so allows the user to expedite the repetitive tasks and allows them to be consistent. More often than not, users will find themselves re-creating the aforementioned assets for each new model. This does not, and should not, be the case.

Most BIM-M platforms allow for the reuse of user-created content from model to model and therefore project to project. In the case of Tekla Structures, users can establish company folders to house these settings and configurations for use throughout all projects. Also, it is easy to parse out certain settings for specific uses. For example, if there are specific settings in drawings or creation of masonry walls that pertain to only one project or a single recurring client, these can be stored separately and accessed when only needed.

The point in going to some detail here is to highlight that advanced workflows involve thinking ahead to maximize productivity and consistency. The ability to manage content that is specific to your company and its needs is key. But it does not stop at how you manage your settings and assets used in the software, but also how you organize and approach your modeling that can make a huge difference.

The biggest key in organizing in a BIM-M model is populating your objects with consistent data. It goes without saying that with masonry there is a lot of identical or repeated objects. Ensuring that an 8x8x16 block is named the same throughout your model makes it far easier to isolate, count, and represent in deliverables. If you'd don't, some are going to get lost or excluded and can add time later down the line to correct. The way you name an object is a great example but the idea here is to apply this to any attribute associated with an object or part. This can range from the material, finish, color, grout mixture, and so on. Consistency is key, so defining settings and organizing them as mentioned previously will allow you to do so with little effort and time.

One other approach that often gets omitted in basic workflows is planning how you are going to model a project. If you have the design/bid documents you can start to break the structures down into phase, lifts, pours, and any other classification that is applicable. Doing so, even on a simple level before modeling allows you to create your model objects in line with a level of organization. It can be expanded as you go but having a plan before executing the work breeds success and efficiency.

An example of this would be breaking the project up into phases and use software-based features such as Tekla Structures Phase Manager to assign objects to the phases you define. The phase itself becomes an attribute of those objects and you can isolate, report, and quantify by phase. Again it doesn't have to be phase per se, but by lift, building, area, and so on.

Working smart by managing your assets and resources, as well as modeling with purpose by planning allows for greater success downstream. This is the foundation of advanced workflows and if your account for later stages of a project in your upfront workflows, then they allow you to leverage what you have done to propel you forward and expand the return on your investment. To that point, let's now focus on what that downstream can look like. Tradition has taught us what we need to produce to build our projects are documents and deliverables which inform our crews of what the requirements may be.

BIM-M allows for easy creation of these documents using model geometry to expedite the creation process and reduce drafting time considerably. That's the basic workflow: create the model, quantify, and then produce drawings as needed for use in the field. But if you are serious about adopting advanced workflows for BIM-M then field use of models is an area that provides a large growth opportunity.

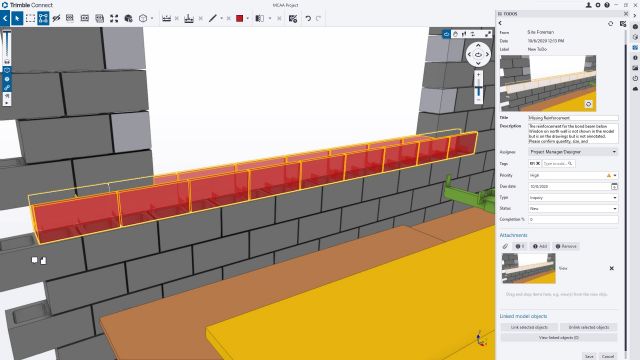

Viewing and collaboration software such as Trimble Connect allows people from all levels of the project to view and interact with BIM-M, other models, and 2D documents. Viewing software often has desktop, web, and mobile applications which are all accessible and easy to learn. Many masonry and construction companies have made efforts to be more eco-friendly and adopt digital media in the field with laptops, tablets, and phones.

So the ability to have access to viewable models in the field is already becoming more commonplace. To boil it down, part of executing an advanced workflow is not just taking those drawings to the field but also models via these types of viewers. Although the process may vary slightly depending on what authoring software and viewer you are using this advanced process is relatively simple to execute and the benefits are numerous.

Having the model in the field allows field crews to instantly gauge the constructability of a project as they need. It not only allows them to associate drawings with model objects but also quantify the model, isolate specific areas, obtain information on objects, and see how it interacts with other model references such as steel, all on their own. Providing this visualization is great but the real value lies in enabling your experts such as crew members, foremen, superintendents, project managers, and so to put their eyes on a comprehensive model before and as it is being built. This provides an unparalleled level of collaboration from one consistent source: your BIM-M model. You will find these key members speaking to the model and addressing constructability concerns before they ever find their way to the field.

With BIM-M in the field, you can easily update the model from the authoring software to address any issues observed. Updating any drawings and model files to the viewer is also quick and easy, providing an easy turnaround on revisions, RFI's or issues encountered. But it doesn't stop there either. Taking the model to the field also provides the ability to status the model and share it instantly back to the native authoring software and provide a current visualization of a project's progress and reported. Lastly, BIM-M models can be used to facilitate field coordination such as pre-job briefs, planning of the day meetings, and safety briefs. This provides a huge value to effective communication and human performance on any job.

Now we've spoken on what advanced workflows are, how to manage our model, and take the full potential of our work out to the field. But what we have not touched upon yet is expansion. Expanding your use of BIM-M is also a component of advanced workflows. With a basic workflow, we're concerned mostly with the structure itself. This is good and a solid initial perspective. But BIM-M can also provide value in other areas and is only limited by your need as a company.

Let's use an example of the number one important thing on a job: safety. Planning for safety is a job in and of itself and requires excellent attention to detail. The reality is we can use our BIM platform to not only model our structure but also equipment such as barriers, scaffolding, netting, kickboards, tie-off points, and the list can go on. Modeling these for planning, placement configuration, and review can bolster the safety on site and ensure that our brothers and sisters go home safely each day. Not to mention this also affords us an accurate quantification of what materials are needed to ensure the safety of our crews and jobsite.

In addition to safety, we can also leverage our BIM-M models to account for many other needs on a job. We can produce layout points from the model using real-world coordinate to provide an accurate layout with our survey crews. Model objects can be associated with software scheduling features to help visual timelines, work crews, as well as visualize and report on planned vs actual timelines. On large jobs, laydown areas can be modeled and even their contents such as materials and equipment.

From there it's relatively easy to provide a manifest or BOM for each palette of material, specs on equipment, and so on. Let us not forget to quickly push an update to our model in our viewing software and associate those documents to the laydown model. This can save considerable time in finding correct materials and avoiding mistakes is utilizing the wrong thing in the field. These are just a few examples, but I am sure by reading this one or two opportunities relevant to you has already popped into your mind.

As you can see advanced workflows for BIM-M are not necessarily a step by step process, that's more of a procedure. They're also not tied to having an advanced skill set. The topics discussed can be executed by those who have a beginner or intermediate skill set, years spent using BIM-M is not required. The key is to move your business and process forward. To use what you have accomplished in BIM-M and advance it to gain more value and accuracy. How you go about doing it looks a little different from company to company but what remains consistent is that it only requires the drive to do so.

About the Author