Brick Brief: Flashing Chimneys

Flashing is an important element in brick masonry's line of defense against water penetration. Flashing may either direct moisture out of a cavity or prevent moisture from entering. Without flashing, any intersection or interruption of materials becomes an avenue for moisture to enter the construction. Several specific areas of potential moisture penetration must be addressed in the flashing of chimneys. This Brick Brief addresses these areas of concern and provides details for optimum performance. The Brick Brief "Proper Chimney Crowns" may also be of interest.

The Base

The base of the chimney is constructed in much the same manner as a brick cavity wall. Flashing must be used at the joint between the foundation and the brickwork. The flashing should extend through the brick wythe and turn up behind the exterior face of the brick, ending in a mortar joint in the interior wythe. Weeps are placed immediately above the flashing.

Intersection with the Roof

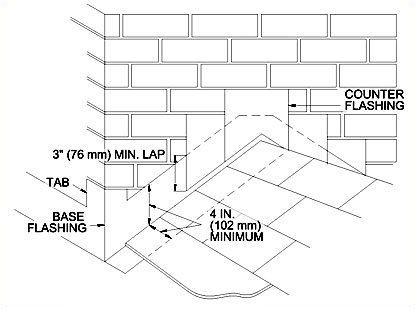

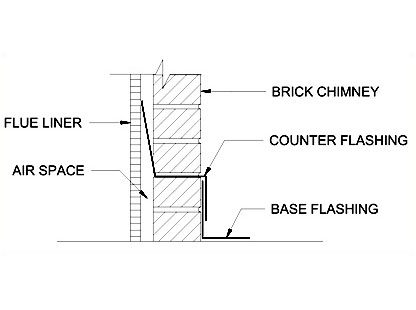

The chimney penetration of the roof must be properly flashed to prevent water from entering the interior of the structure. Base and counter flashing must be installed at the interface. Base flashing is placed first, starting with the lower ends of the faces of the chimney perpendicular to the ridgeline, with tabs at each corner. The base flashing should extend a minimum of four inches (102 mm) along the roof and four inches (102 mm) up the chimney face as shown in Figure 1. Counter flashing is then lapped over the base flashing a minimum of three inches (76 mm), extended through the chimney wall, and turned up at an angle into the air space to collect water draining down the back of the brickwork as shown in Figure 2. All joints and laps in the base and counter flashing must be completely sealed. Weeps are not typically included.

The Chimney Crown

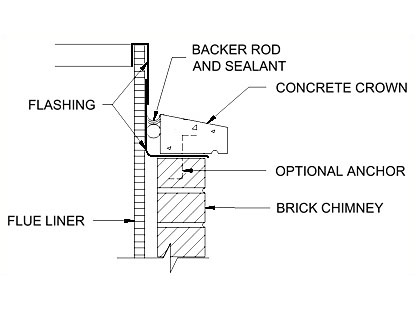

The area around the chimney crown is often overlooked as a source of moisture penetration. Flashing and sealant are important here to prevent water from entering the space between the chimney wall and the flue liner. The first piece of flashing should be placed directly below the chimney crown, extend through the brick wythe, and turn up against the outer face of the flue liner. This flashing should form a drip above the outside chimney face. A second piece of flashing should be folded over the top of the flue liner and extended down the outside to lap the first piece of flashing, as shown in Figure 3. For further information on chimney crown flashing, refer to Brick Brief "Proper Chimney Crowns."

Copper

Copper is durable, able to withstand elevated temperatures in the chimney, available in special performed shapes, and is an excellent moisture barrier. Copper can be safely embedded in fresh mortar and will not deteriorate in continuously saturated, hardened mortar unless excessive chlorides are present. Copper flashing may stain the concrete crown or brick masonry.

Stainless Steel

Stainless steel is an excellent flashing material. It provides a good water barrier, high-temperature resistance, and has excellent chemical resistance. ASTM A 240, Type 304 should be specified. The minimum thickness used should be 0.01 inch (0.25 mm).

Galvanized Steel

The life of galvanized steel flashing depends on the thickness of the zinc coating. However, thicker coatings may crack when folding the flashing. Galvanized steel is not recommended.

Aluminum

The alkalis present in fresh mortar will attack aluminum. Thus, aluminum should not be used as a flashing material in brick masonry.

About the Author

The Brick Industry Association (BIA) is the national trade association representing distributors and manufacturers of clay brick and suppliers of related products and services. Go to www.gobrick.com for more information.

The Brick Industry Association's "Brick Briefs" are short discussions of a particular topic. The information contained herein is based on the experience of Brick Industry Association technical staff and must be used with good technical judgment. Final decisions on the use of this information must rest with the project designer and owner. For more information, please visit www.gobrick.com.