How Do You Know Your Plank is Safe?

Ask a representative from any of the leading U.S. scaffold plank manufacturers what he or she thinks is the most important issue in the planking industry and you undoubtedly will get the same response each time: non-regulated manufacturing and sales of scaffold planks. The issue may be as old as the OSHA guidelines for solid sawn (DI 65) and laminated veneer lumber (LVL) plank, but it still weighs heavy on the minds of legitimate plank manufacturers. Now, through their affiliation with the Scaffold Industry Association (SIA) and its Plank & Platform Council (PPC), many American scaffold plank suppliers are working to issue a series of guidelines (first for LVL, then DI 65) that should help contractors to know what questions to ask when purchasing planks.

Masonry spoke with several manufacturers about this important topic and the new guidelines, which should be available later this year. It is important to note that the SIA is an educational association, and not an enforcement organization. The PPC's intent is to provide contractors with the information they need to make the best buying decisions.

"It's a nationwide problem and, until the contractor steps up, takes this issue seriously, and gets themselves informed, there will still be a great deal of non-compliant wood sold as plank," said Mike Gilleran, owner of McCausey Lumber in Roseville, Mich., and a member of the PPC. Gilleran also stressed the fact that OSHA does not approve any company's board, they only recognize certain grades of lumber and certain manufacturers of laminated plank.

"There isn't any real policing being done of what's being used out there, in my opinion. ... OSHA has limited resources, and they can't possibly address each and every job site on a regular basis," Gilleran said.

Colby Hubler, president of sales and marketing for Mill Direct Lumber Sales Inc. in Tualatin, Ore., and chairman of the PPC, said the non-compliant planks are those that look and feel like compliant products but, because of the lack of quality control in some countries, the final product does not meet the U.S. industry standard. "The effect is potentially a plank that cannot handle the proper loads and tragically injury [has occurred] in some cases," he said. "With respect to solid sawn plank, we are seeing 'non-scaffold' grade lumber being sold and used as scaffold plank. Not only is this in violation of OSHA, but it is a deliberate disregard for safety."

Educating the contractor is key, Hubler said, to ensuring that only safe scaffold plank is used on construction sites. "The goal is to develop a dialogue of questions and answers between the buyer and the supplier that will outline the products' compliance, the manufacturing process, how to identify the plank and if the supplier has the resources to support the product from all angles," Hubler said. "We feel, if the buyer is aware of what to look for in a legitimate manufacturer and a compliant scaffold plank, eventually there will be no room for a substandard, unsafe product."

John Warlikowski, LVL product manager for Kennison Forest Products Inc. in Riverside, Calif., and a member of the PPC, couldn't agree more. He first became aware of the "knock-off" LVL scaffold planks, as he calls them, about one year ago and actually had the questionable planks tested by an independent laboratory. "I was able to obtain several hundred of the planks that had not been used, but were in brand new, off-the-shelf, ready to sell condition," Warlikowski said. He then asked that the planks be evaluated based on what was embossed along their edges.

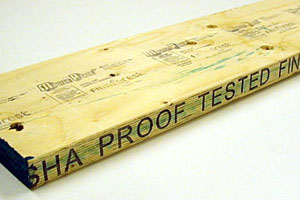

"The edges read, 'Proof Tested Scaffold Plank 6-20-05 2.2E OSHA.' Any unsuspecting contractor or building material supplier would certainly believe they were purchasing legitimate LVL planks. However ... many of the planks had begun to delaminate. Several of the planks had putty applied to the surface to hide missing sections of veneer. That is when [the lab] started noticing all the little things that legitimate manufactures' do to ID their product were also missing: no independent third-party inspection stamp, no face stamp with mill number, and MOE [Modulus of Elasticity] or Fb [Fiber in Bending] rating."

Warlikowski said the physical testing of the knock-off plank also was alarming. "Over 80 percent of the planks did not meet the claimed 2.2E, Modulus of Elasticity rating," he said. "Only 30 percent met the minimum L/60 OSHA requirement for deflection. At the end of the day, it was determined that these boards might make an OK mudsill."

Although the SIA's guidelines on purchasing LVL plank are not yet finalized, the following topics are likely to be part of the final draft and would be among the major points of concern for contractors looking to purchase plank: guidelines on the physical/mechanical properties of scaffold plank; preferred manufacturing procedures; proper plank identification markings and codes; recommended literature and standards; and manufacturer/supplier certifications.

Gilleran said of the guidelines: "There are some grey areas within the OSHA and ANSI standards. When they were written so many years ago, probably no one foresaw anything different going on. What this checklist is supposed to do is bridge that gap."

For more information on the guidelines, visit the SIA's website at www.scaffold.org.

About the Author

Cory Sekine-Pettite is an editor for Lionheart Publishing and was the founding editor of Masonry Design magazine.