May 15, 2009 8:02 AM CDT

How difficult is it to re-brand a company? If it’s done right, it’s like clockwork. Lafarge is currently rolling out new eco-friendly packaging for its entire family of cement products in the United States and Canada. The look of the new bags was unveiled during the World of Masonry in Las Vegas in January, with examples showcased recently at The Brick Show in Marco Island, Fla.

Featuring a fresh look, the newly redesigned packaging is part of a larger global effort to harmonize all elements of the company’s brand and make these visual signatures expressive, distinctive and unquestionably Lafarge. Bags for each product type are printed in a different color, and label content – such as safety and handling information, warranty, specifications, storage and mixing instructions – has been updated as appropriate.

The distinctive new look of the cement packaging is more consistent with Lafarge’s brand image and better reflects our vision and values. It is part of a larger, corporate-wide effort to ensure conformity of the Lafarge brand globally.

Sustainability is a major focus for Lafarge, and environmentally friendly packaging is just one example of how the company supports product stewardship practices in the design, manufacture, distribution and application of its products. In 2009, and for the fifth year in a row, the company was listed in the “Global 100 Most Sustainable Corporations in the World.”

As a member of both the U.S. Green Building Council and the Canada Green Building Council, Lafarge works with leaders from across the building industry to promote environmentally responsible building practices. It is also an industry leader in the reuse of byproducts from other manufacturing industries that would normally be destined for landfill.

Lafarge operates the most far-reaching manufacturing and distribution network for moving products to customers throughout North America. The company’s comprehensive lineup of packaged cement products includes various types of quality Portland cements, as well as masonry and mortar cements used in commercial and residential brick, block and stone masonry construction. It also includes specialty cement products, such as NewCem slag cement, MaxCem blended cement, stucco and fly ash.

Lafarge masonry cements are manufactured using the highest quality clinker and a high-calcium carbonate limestone interground with plasticizers. These ingredients are accurately proportioned and controlled throughout the manufacturing process to assure a uniform product:

Type N: a general-purpose mortar used for above-grade construction

Type S: used when high or moderate strengths are necessary

Type M: used when high compressive strengths are needed.

Lafarge mortar cements provide excellent workability, reduced permeability, improved bond strength and feature the advantage of uniform proportioning associated with mortar cements. Each type features specialized qualities to meet the demands unique to each project:

Type N: recommended for exterior above-grade, load-bearing walls and interior load-bearing walls

Type S: recommended for exterior load-bearing and foundation walls when increased strengths are required

Type M: recommended for below-grade construction when high-compressive strengths are required.

Extreme Makeover

Lafarge packaging gets a fresh, new look, while becoming more eco-friendly

By Steve Meima

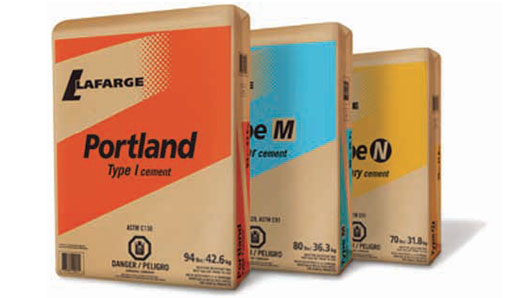

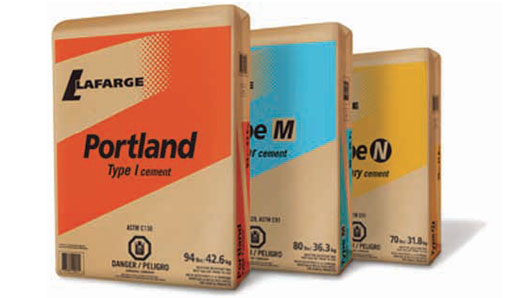

New Lafarge packaging features a distinctive design and a fresh look, but the bags contain the same top-quality products. They’re also made from unbleached, natural kraft paper. Image courtesy of Lafarge Cement.

How difficult is it to re-brand a company? If it’s done right, it’s like clockwork. Lafarge is currently rolling out new eco-friendly packaging for its entire family of cement products in the United States and Canada. The look of the new bags was unveiled during the World of Masonry in Las Vegas in January, with examples showcased recently at The Brick Show in Marco Island, Fla.

Featuring a fresh look, the newly redesigned packaging is part of a larger global effort to harmonize all elements of the company’s brand and make these visual signatures expressive, distinctive and unquestionably Lafarge. Bags for each product type are printed in a different color, and label content – such as safety and handling information, warranty, specifications, storage and mixing instructions – has been updated as appropriate.

The distinctive new look of the cement packaging is more consistent with Lafarge’s brand image and better reflects our vision and values. It is part of a larger, corporate-wide effort to ensure conformity of the Lafarge brand globally.

Environmentally Friendly Packaging

In response to growing interest in sustainable packaging, Lafarge’s new cement bags are made from unbleached, natural kraft paper. Kraft paper is a 100 percent biodegradable natural product that decomposes naturally within a few weeks [of being discarded]. A highly recyclable product, unbleached natural kraft paper also minimizes chemical processing requirements.Sustainability is a major focus for Lafarge, and environmentally friendly packaging is just one example of how the company supports product stewardship practices in the design, manufacture, distribution and application of its products. In 2009, and for the fifth year in a row, the company was listed in the “Global 100 Most Sustainable Corporations in the World.”

As a member of both the U.S. Green Building Council and the Canada Green Building Council, Lafarge works with leaders from across the building industry to promote environmentally responsible building practices. It is also an industry leader in the reuse of byproducts from other manufacturing industries that would normally be destined for landfill.

New on Outside, Same on Inside

While the appearance of Lafarge’s cement packaging has changed, the products, bag weights and quality characteristics remain the same. Some product names, however, have been changed to harmonize all elements of the Lafarge brand: U.S. Cement custom blends are now sold as Lafarge custom blends, and Trinity products are sold as Lafarge products. Certain brands, such as Magnolia, continue to be sold in specific geographic areas.Lafarge operates the most far-reaching manufacturing and distribution network for moving products to customers throughout North America. The company’s comprehensive lineup of packaged cement products includes various types of quality Portland cements, as well as masonry and mortar cements used in commercial and residential brick, block and stone masonry construction. It also includes specialty cement products, such as NewCem slag cement, MaxCem blended cement, stucco and fly ash.

Lafarge masonry cements are manufactured using the highest quality clinker and a high-calcium carbonate limestone interground with plasticizers. These ingredients are accurately proportioned and controlled throughout the manufacturing process to assure a uniform product:

Type N: a general-purpose mortar used for above-grade construction

Type S: used when high or moderate strengths are necessary

Type M: used when high compressive strengths are needed.

Lafarge mortar cements provide excellent workability, reduced permeability, improved bond strength and feature the advantage of uniform proportioning associated with mortar cements. Each type features specialized qualities to meet the demands unique to each project:

Type N: recommended for exterior above-grade, load-bearing walls and interior load-bearing walls

Type S: recommended for exterior load-bearing and foundation walls when increased strengths are required

Type M: recommended for below-grade construction when high-compressive strengths are required.

Market Awareness Campaign

To support this rebranding initiative, Lafarge has launched a communications campaign to increase awareness among customers, including dealers and distributors, contractors and masons. In addition to advertising, public relations and promotional literature, this customer-focused communications program includes a new, branded Web site at www.newcementbags.com that links to visuals of all the new cement packaging.About the Author

Steve Meima is the Marketing Communications Manager for Lafarge North America.