August 10, 2011 7:00 AM CDT

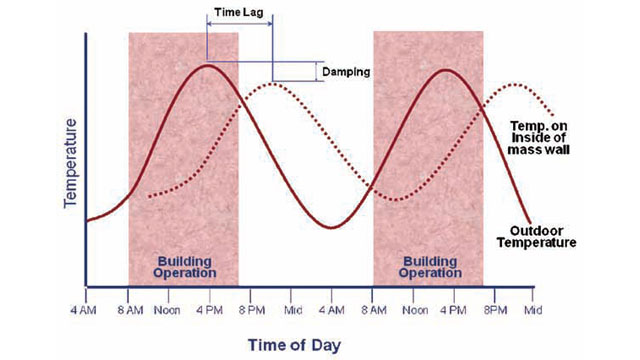

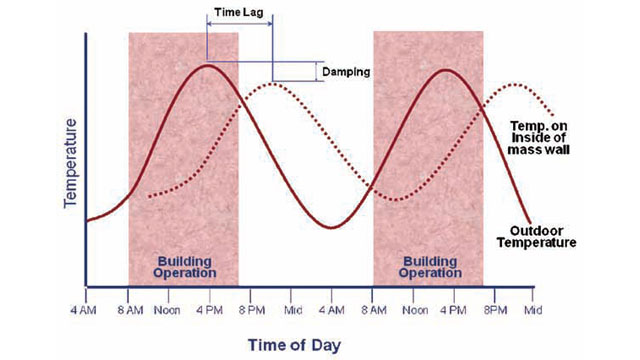

It is important to note that R-values, alone, do not fully describe the thermal performance of a concrete masonry wall. Masonry’s thermal performance depends upon its steady-state thermal characteristics (described by R-value or U-factor) as well as the thermal mass (heat capacity) properties of the wall assembly. Because of its comparatively high density and specific heat, masonry provides effective thermal storage. Masonry walls remain warm or cool long after the heat or air conditioning has shut off. This inherent quality reduces peak heating and cooling loads, moderates indoor temperature swings, and shifts heating and cooling loads to off-peak hours (see Figure 1). Due to these significant benefits of thermal mass, concrete masonry buildings can provide similar energy performance to more heavily insulated frame buildings.

“Mass walls shall include walls weighing at least (1) 35 pounds per square foot of wall surface area or (2) 25 pounds per square foot of wall surface area if the material weight is not more than 120 pounds per cubic foot.”

The 2009 Washington State Energy Code and 2007 ASHRAE 90.1 contain a more technical definition which is about equivalent to the IECC.

“Mass wall: A wall with an HC (heat capacity) exceeding (1) 7 Btu/ft2 – °F or (2) 5 Btu/ft2 – °F, provided that the wall has a material unit weight not greater than 120 lb/ft3.”

Heat capacity is a product of a material’s mass, or weight, multiplied by its specific heat. Since the specific heat of concrete masonry is 0.21, the two code definitions for a “mass wall” are similar.

b All cores to be filled. At least 50 percent of cores must be filled with vermiculite or equivalent fill insulation.

c All cores except bond beams must contain rigid insulation inserts approved for use in reinforced masonry walls.

There has been some confusion regarding the calculation of heat capacity values to meet the “mass wall” definition of the Washington code. To determine the heat capacity of a wall assembly simply take the weight per square foot of the wall layer and multiply it by the material’s specific heat. Then add the values together if there is more than one layer. The calculation can be structured in tabular form as shown below.

The heat capacity values in Table 1 include common single-wythe masonry walls as found in Table 10-9 of the code. In addition, values for brick veneer and a masonry cavity wall have been included. To identify mass walls for compliance with Table 13-1 and 13-2, use the heat capacity values directly from code Table 10-9 or other recognized sources.

1 Nonresidential walls may be ASTM C90 concrete block walls, ungrouted or partially grouted at 32 inches or less on center vertically and 48 inches or less on center horizontally, with ungrouted cores filled with material having a maximum thermal conductivity of 0.44 Btu-in/h•ft2•°F.T

Regardless of a project’s energy efficiency and sustainability design goals, concrete masonry walls can help to meet these goals. In addition to the thermal mass benefits discussed in this article, concrete masonry is a locally produced construction material that has superior durability minimizing the need for repair or replacement. It also provides aesthetic appeal, structural strength and resistance to fire.

Nonresidential energy code compliance with concrete masonry

Thermal mass is the energy saver in masonry buildings

By Tom Young

The benefits of thermal mass permit concrete masonry assemblies to have less insulation than lightweight frame systems.

The concept that massive walls absorb and retain heat, to be later released, has been understood since the time of the world’s earliest structures, many of which were built to benefit from the delaying effect of mass on the transfer of heat. This physical property, combined with the dynamic temperature cycles a building is subjected to, allows masonry materials to be utilized effectively in the design of energy-efficient buildings. The benefits of thermal mass have been incorporated into modern energy code requirements, permitting concrete masonry assemblies to have less insulation than lightweight frame systems. It is important to note that R-values, alone, do not fully describe the thermal performance of a concrete masonry wall. Masonry’s thermal performance depends upon its steady-state thermal characteristics (described by R-value or U-factor) as well as the thermal mass (heat capacity) properties of the wall assembly. Because of its comparatively high density and specific heat, masonry provides effective thermal storage. Masonry walls remain warm or cool long after the heat or air conditioning has shut off. This inherent quality reduces peak heating and cooling loads, moderates indoor temperature swings, and shifts heating and cooling loads to off-peak hours (see Figure 1). Due to these significant benefits of thermal mass, concrete masonry buildings can provide similar energy performance to more heavily insulated frame buildings.

Figure 1 - The Benefits of Thermal Mass on Building Energy Efficiency

Although in general higher R-values reduce heat flow through a building element, you can quickly reach a point where R-values have a diminishing impact upon the overall building envelope energy use. Adding excessive amounts of insulation to a mass wall, for example, is not cost-effective for most nonresidential buildings in the northwest. Paybacks periods for the building owner are far too long. It makes more sense to invest in energy efficiency measures other than wall insulation.What is a mass wall?

Since national and northwest energy codes provide different requirements for mass walls, the question can be asked, what is the definition of a “mass wall?” The 2010 Oregon Energy Code and 2009 IECC contain the following definition:“Mass walls shall include walls weighing at least (1) 35 pounds per square foot of wall surface area or (2) 25 pounds per square foot of wall surface area if the material weight is not more than 120 pounds per cubic foot.”

The 2009 Washington State Energy Code and 2007 ASHRAE 90.1 contain a more technical definition which is about equivalent to the IECC.

“Mass wall: A wall with an HC (heat capacity) exceeding (1) 7 Btu/ft2 – °F or (2) 5 Btu/ft2 – °F, provided that the wall has a material unit weight not greater than 120 lb/ft3.”

Heat capacity is a product of a material’s mass, or weight, multiplied by its specific heat. Since the specific heat of concrete masonry is 0.21, the two code definitions for a “mass wall” are similar.

- HC = 35(lb/ft2) x 0.21 = 7.35

- HC = 25(lb/ft2) x 0.21 = 5.25

| Table 1 - Heat Capacity Values (Btu/ft2 - °F) | ||

| Wall | Partial Grout |

Solid Grout |

| 8" CMU | 9.65 | 15.00 |

| 12" CMU | 14.50 | 25.60 |

| 8" Brick |

10.90 | 16.40 |

| CMU Cavity Wall | 15.00 | 20.35 |

| Wall | No Grout | |

| 4" brick Veneer (wood studs) | 7.40 | - |

| 4" brick Veneer (metal studs) | 7.20 | - |

Oregon Code

The masonry wall U-factor requirements in the new 2010 Oregon Energy Code have not changed from the previous 2007 code for Climate Zone 1. The maximum glazing fraction has been reduced from 40 percent to 30 percent. Former Climate Zone 2 has been merged with Climate Zone 1. Table 2 lists the mass wall requirements in the 2010 Oregon Energy Code.| Table 2 - Nonresidential Mass Wall Performance Requirements |

|||

| COMPONENT | Maximum Glazing Fraction | Maximum U-Factor | Maximim R-Value |

| Masonry, with integral insulationb |

15% | 0.300 | - |

| Masonry, with integral insulationc | 30% | 0.210 | - |

| Masonry, with interior insulation | 30% | 0.130 | 11 |

b All cores to be filled. At least 50 percent of cores must be filled with vermiculite or equivalent fill insulation.

c All cores except bond beams must contain rigid insulation inserts approved for use in reinforced masonry walls.

Washington Code

The masonry wall U-factor requirements in the new 2009 Washington State Energy Code have not changed from the previous 2006 code. These prescriptive provisions are still found in code Tables 13-1 and 13-2 and are listed in Table 3 of this article. The concrete masonry wall option is no longer a table footnote and is now found under “mass walls” in the body of the table for above-grade walls. Area weighted averaging of U-factors is allowed for compliance under Section 1322. Note that footnote 1 of Table 13-1 (Climate Zone 1) still permits an exposed, partially-grouted concrete masonry wall to comply when the ungrouted cores are filled with foam, rigid inserts, or poured insulation. Also, note that the previous minimum heat capacity value of 9.0 has been changed to either 7.0 or 5.0 as discussed previously.| Component | Weight (lb/ft2) |

x Fraction of Wall |

x Specific Heat |

= HC |

| 8" Partial Grouted | 46.00 | 1.00 | 0.21 | 9.66 |

| 2x4 Wood Studs | 9.30 | 0.15 | 0.33 | 0.46 |

| R-11 Batt | 0.25 | 0.85 | 0.30 | 0.06 |

| 5/8" Gypsuim Board | 2.60 | 1.00 | 0.26 | 0.68 |

| Total HC = 10.86 |

||||

There has been some confusion regarding the calculation of heat capacity values to meet the “mass wall” definition of the Washington code. To determine the heat capacity of a wall assembly simply take the weight per square foot of the wall layer and multiply it by the material’s specific heat. Then add the values together if there is more than one layer. The calculation can be structured in tabular form as shown below.

The heat capacity values in Table 1 include common single-wythe masonry walls as found in Table 10-9 of the code. In addition, values for brick veneer and a masonry cavity wall have been included. To identify mass walls for compliance with Table 13-1 and 13-2, use the heat capacity values directly from code Table 10-9 or other recognized sources.

| Table 3. Washington Building Envelope Requirements - Nonresidential Mass Walls | |

| Climate Zone 1 | U-0.1501 or R.5.7 continuous insulation |

| Climate Zone 2 |

U-0.123 or R.7.6 continuous insulation |

1 Nonresidential walls may be ASTM C90 concrete block walls, ungrouted or partially grouted at 32 inches or less on center vertically and 48 inches or less on center horizontally, with ungrouted cores filled with material having a maximum thermal conductivity of 0.44 Btu-in/h•ft2•°F.T

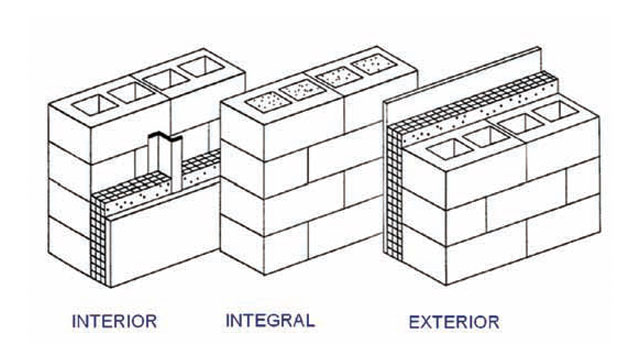

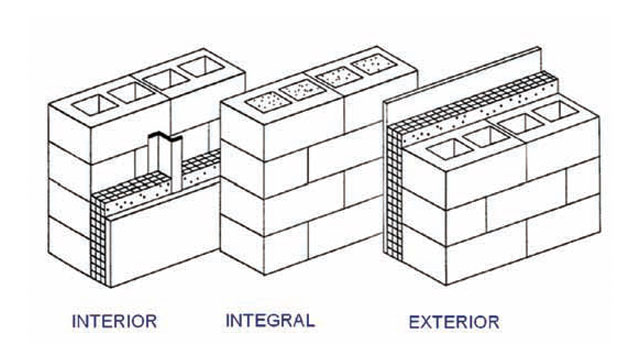

Figure 2 - Insulation Options with Concrete Masonry Single-Wythe Walls

Summary

The masonry (mass) wall requirements of the new Oregon and Washington state energy codes have not changed. Most common concrete masonry wall systems will qualify as “mass walls” meeting the wall weight or heat capacity provisions of these codes. They are eligible to comply with the codes using the lower mass wall requirements in the prescriptive compliance tables. There are a variety of masonry wall types and insulation options available for code compliance. Single-wythe walls can be insulated as shown in Figure 2.Regardless of a project’s energy efficiency and sustainability design goals, concrete masonry walls can help to meet these goals. In addition to the thermal mass benefits discussed in this article, concrete masonry is a locally produced construction material that has superior durability minimizing the need for repair or replacement. It also provides aesthetic appeal, structural strength and resistance to fire.

Originally published in Masonry magazine.

About the Author

Tom Young, P.E., is the executive director of the Northwest Concrete Masonry Association. He has worked for the masonry industry for more than 35 years and serves on numerous code development and technical committees.

This article first appeared in MASONRY, a publication of the Masonry Industry Promotion Group in Spokane, Wash.