October 10, 2011 7:00 AM CDT

Tony DiAngelus is senior founder/CEO of Krando Metal Products Inc., which manufactures all types of anchors to support stone used for interior or exterior veneers. Stephen Getz, BSCE, is owner and president of Construction Tie products, which produces and designs various American-made masonry anchoring hardware products for applications in new and existing masonry buildings. Mike Ripley is National Sales Manager for Wire-Bond, which produces adjustable-type anchoring systems, a common method of tying masonry veneers to steel stud backups, in addition to more products.

Masonry: How did 2010 compare to 2009 for your company, and how is 2011 looking thus far?

Tony DiAngelus, Krando: The year 2009 for Krando Metal, like many other businesses, was challenging, due to the tough economic times. With careful planning and proper investments in machinery and marketing tactics, 2010 turned out to be a prosperous year for us. Thus far, 2011 is looking very positive, and we are seeing signs of new construction in the works.

We did not have to vary our products that we offer, because we do such a broad array of manufacturing here; so we aren’t just limited to the masonry field. We also do structural work, food service and ornamental shape cutting as well.

Steve Getz, CTP: Although 2010 experienced a slight improvement over the results of 2009, it still lacks in comparison to prior years. As is typical in the industry, the start of sales activity in 2011 following the holidays was sluggish. However, based on ambitious bidding activity, we are optimistic about the rest of the year.

Recognizing the challenges of the market place in 2009 and 2010, and in a desire to continually improve and expand our offerings to our customers, CTP has added new product lines to bolster opportunity offerings and re-engineered products for optimizing user costs. We regularly tweak the marketing aspects of CTP products for the architectural and engineering community to embrace.

Mike Ripley, Wire-Bond: Volume in 2010 was very disappointing, even compared to 2009, when we saw a big downturn from the previous year. Raw materials such as rod and zinc increased, along with energy costs to operate our plants, sending margins down. On the positive side, we did gain some momentum in the third and fourth quarters, after one of our major competitors was sold late in the first quarter.

We are seeing a little daylight in the first quarter of 2011 as volume and sales dollars have both increased. We have pockets where some dealers are positive, due to an increase in quotes and jobs that were shelved in 2009 and 2010 that are finally ready to start. Overall, we have a mixed bag of confidence among customers, and we forecast a slight recovery in 2011.

Wire-Bond has broadened their product line as we invested in machinery to manufacture copper flashings and accessories, like termination bar and drip edge. Our goal is to be a one-stop shop for quality masonry accessories.

Masonry: What challenges have you faced during the last year regarding your products?

DiAngelus: One of the challenges that we faced over the last few years is material costs rising. What we here at Krando Metal have done is looked at the industry and foreseen where it’s heading. By doing this, we have been able to stock our facility with material, so that we can give competitive pricing.

Trying to keep up with supplier demand isn’t much of a challenge for us. We have outfitted this company with the machinery and personnel, so that no job is either too big or too small. Our anchors are manufactured in house and made to order.

Labor issues haven’t really been a problem for us. We have had the same personnel working in our facility for years. Every one of them has been trained on each machine, so they are all well versed with the machinery in our facility.

Getz: In 2010, the supply chain service levels were impacted as material producers and secondary source material finishers cut back on employees, shortened work weeks, and extended holiday shut downs in an effort to balance their operating cash flows. This trickled down to the suppliers, and their ability to provide finished products to the market place, as the “just in time” inventory principle was at times abruptly interrupted. This scenario hasn’t changed (yet) for 2011, and it has the potential to make 2011 a daunting balancing act for price stability, inventory control, and product availability.

Ripley: Rising steel prices continue to be a major challenge for us. Since January of 2010, we have experienced six significant price increases. The weak dollar, rising production cost at mills and less competition from imports have allowed domestic steel mills to raise prices.

Another challenge is our competitors importing products from China. The Chinese government gives financial incentives to Chinese companies to export finished goods as opposed to raw materials or semi-finished goods. This takes jobs (manufacturing jobs) away from Americans. Wire-Bond manufactures all its quality products in the United States – a difficult task with price pressures from our competitors.

Masonry: What role does technology play in your business?

DiAngelus: Technology has played a huge role in where our industry is today. Newer machinery has helped to increase production methods. A new piece of technology that we just added to our website is the ability to order anchors directly over the internet, so that phone calls are minimal.

Smartphones have played a huge role in how we operate today, because we now have the ability to email drawings to workers in the field so they can be viewed on their phones. Most of the people we deal with aren’t always in their office, so now we all have the ability to be on site while viewing specific drawings.

Getz: CTP is constantly adapting to the electronic media communications network. Design professionals are carrying “less baggage” regarding literature, binders and paper while relying more upon the 24-7 internet communication capabilities. Besides obvious internet searches, the ability to instantly interact with customer inquiries when electronic copies of site photos, plans, specifications, details, etc. are available makes for exciting opportunities.

Ripley: Technology plays a huge part in helping us be more efficient in the manufacturing process. We have invested in computer-controlled, wire-forming machines (CNC), computer-controlled safety equipment on automatic stamping and welding machines, and started upgrading our ladder machines to Servo motors that are more efficient and produce less scrap. The 3-D CNC machines allow us to manufacture our patented CoreLock rebar positioners in seconds, versus minutes manually. This dramatically cuts costs and allows us to supply higher quality products that save the contractor money at competitive prices.

All of our sales representatives have smart phones, which allow them to stay in close contact with their customers. They can now quote jobs while on the road, the moment they receive the email, instead of waiting until the evening when they normally use their laptops.

We have also updated our software programs this year and continue to add features as needed.

Masonry: What do you see for the future of the masonry and construction industries?

DiAngelus: We are very optimistic for what the future of the construction industry holds. We know that it will be a slow return, but this industry will be back to where it was. This industry is too big and too strong for it not to come back; construction is the foundation of our economy. We look at it as a “glass half full, not half empty.”

Getz: There will always be a desire for masonry buildings and a need for preserving existing masonry structures. As an industry, there are two trains of thought that require a conscientious effort on our part to stay above the status quo. One is to remain empathic with building owners' needs for cost-effective masonry construction designs and techniques, and to continue to educate the tradesman on new materials and product technologies. The result of our efforts helps propel the customers’ decision toward a value-added masonry building investment. Second, we cannot become complacent with alternative material construction products intended to replicate the masonry “look,” yet fall far below the performance benefits of authentic masonry.

Ripley: We feel that the future of the masonry/construction industries is bright, but challenging. The industry has the most visually appealing product for veneers, no contest. Our history of providing products that endure all types of weather conditions, fire and most seismic reactions are proof of a long-lasting, superior product.

Unfortunately, during an extended slow period, companies have to make some tough decisions. Keeping your core group intact is essential in surviving now and in the future. It may mean taking work at lower margins or working in areas that are further from home, but it is a must to continue to generate revenues with key personnel to survive.

Learning from the masters

Connectors, anchors and fasteners

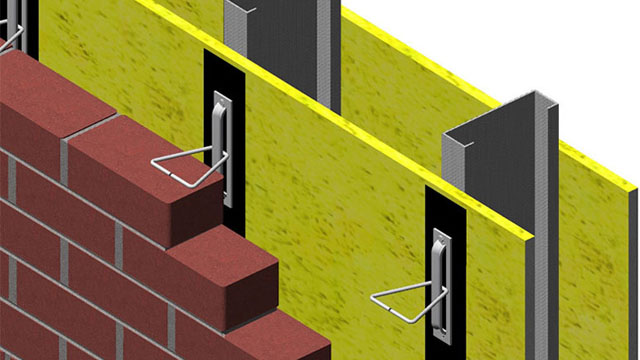

Image Courtesy of Wire-Bond

Like any industry, the anchors, connectors and fasteners industries have faced trying, if not impossible, economic times during the last three years. Masonry spoke with three of this industry’s leaders to learn what it takes to survive, sustain and move forward when faced with adversity beyond their control. Tony DiAngelus is senior founder/CEO of Krando Metal Products Inc., which manufactures all types of anchors to support stone used for interior or exterior veneers. Stephen Getz, BSCE, is owner and president of Construction Tie products, which produces and designs various American-made masonry anchoring hardware products for applications in new and existing masonry buildings. Mike Ripley is National Sales Manager for Wire-Bond, which produces adjustable-type anchoring systems, a common method of tying masonry veneers to steel stud backups, in addition to more products.

Masonry: How did 2010 compare to 2009 for your company, and how is 2011 looking thus far?

Tony DiAngelus, Krando: The year 2009 for Krando Metal, like many other businesses, was challenging, due to the tough economic times. With careful planning and proper investments in machinery and marketing tactics, 2010 turned out to be a prosperous year for us. Thus far, 2011 is looking very positive, and we are seeing signs of new construction in the works.

We did not have to vary our products that we offer, because we do such a broad array of manufacturing here; so we aren’t just limited to the masonry field. We also do structural work, food service and ornamental shape cutting as well.

Steve Getz, CTP: Although 2010 experienced a slight improvement over the results of 2009, it still lacks in comparison to prior years. As is typical in the industry, the start of sales activity in 2011 following the holidays was sluggish. However, based on ambitious bidding activity, we are optimistic about the rest of the year.

Recognizing the challenges of the market place in 2009 and 2010, and in a desire to continually improve and expand our offerings to our customers, CTP has added new product lines to bolster opportunity offerings and re-engineered products for optimizing user costs. We regularly tweak the marketing aspects of CTP products for the architectural and engineering community to embrace.

Mike Ripley, Wire-Bond: Volume in 2010 was very disappointing, even compared to 2009, when we saw a big downturn from the previous year. Raw materials such as rod and zinc increased, along with energy costs to operate our plants, sending margins down. On the positive side, we did gain some momentum in the third and fourth quarters, after one of our major competitors was sold late in the first quarter.

We are seeing a little daylight in the first quarter of 2011 as volume and sales dollars have both increased. We have pockets where some dealers are positive, due to an increase in quotes and jobs that were shelved in 2009 and 2010 that are finally ready to start. Overall, we have a mixed bag of confidence among customers, and we forecast a slight recovery in 2011.

Wire-Bond has broadened their product line as we invested in machinery to manufacture copper flashings and accessories, like termination bar and drip edge. Our goal is to be a one-stop shop for quality masonry accessories.

Masonry: What challenges have you faced during the last year regarding your products?

DiAngelus: One of the challenges that we faced over the last few years is material costs rising. What we here at Krando Metal have done is looked at the industry and foreseen where it’s heading. By doing this, we have been able to stock our facility with material, so that we can give competitive pricing.

Trying to keep up with supplier demand isn’t much of a challenge for us. We have outfitted this company with the machinery and personnel, so that no job is either too big or too small. Our anchors are manufactured in house and made to order.

Labor issues haven’t really been a problem for us. We have had the same personnel working in our facility for years. Every one of them has been trained on each machine, so they are all well versed with the machinery in our facility.

Getz: In 2010, the supply chain service levels were impacted as material producers and secondary source material finishers cut back on employees, shortened work weeks, and extended holiday shut downs in an effort to balance their operating cash flows. This trickled down to the suppliers, and their ability to provide finished products to the market place, as the “just in time” inventory principle was at times abruptly interrupted. This scenario hasn’t changed (yet) for 2011, and it has the potential to make 2011 a daunting balancing act for price stability, inventory control, and product availability.

Ripley: Rising steel prices continue to be a major challenge for us. Since January of 2010, we have experienced six significant price increases. The weak dollar, rising production cost at mills and less competition from imports have allowed domestic steel mills to raise prices.

Another challenge is our competitors importing products from China. The Chinese government gives financial incentives to Chinese companies to export finished goods as opposed to raw materials or semi-finished goods. This takes jobs (manufacturing jobs) away from Americans. Wire-Bond manufactures all its quality products in the United States – a difficult task with price pressures from our competitors.

Masonry: What role does technology play in your business?

DiAngelus: Technology has played a huge role in where our industry is today. Newer machinery has helped to increase production methods. A new piece of technology that we just added to our website is the ability to order anchors directly over the internet, so that phone calls are minimal.

Smartphones have played a huge role in how we operate today, because we now have the ability to email drawings to workers in the field so they can be viewed on their phones. Most of the people we deal with aren’t always in their office, so now we all have the ability to be on site while viewing specific drawings.

Getz: CTP is constantly adapting to the electronic media communications network. Design professionals are carrying “less baggage” regarding literature, binders and paper while relying more upon the 24-7 internet communication capabilities. Besides obvious internet searches, the ability to instantly interact with customer inquiries when electronic copies of site photos, plans, specifications, details, etc. are available makes for exciting opportunities.

Ripley: Technology plays a huge part in helping us be more efficient in the manufacturing process. We have invested in computer-controlled, wire-forming machines (CNC), computer-controlled safety equipment on automatic stamping and welding machines, and started upgrading our ladder machines to Servo motors that are more efficient and produce less scrap. The 3-D CNC machines allow us to manufacture our patented CoreLock rebar positioners in seconds, versus minutes manually. This dramatically cuts costs and allows us to supply higher quality products that save the contractor money at competitive prices.

All of our sales representatives have smart phones, which allow them to stay in close contact with their customers. They can now quote jobs while on the road, the moment they receive the email, instead of waiting until the evening when they normally use their laptops.

We have also updated our software programs this year and continue to add features as needed.

Masonry: What do you see for the future of the masonry and construction industries?

DiAngelus: We are very optimistic for what the future of the construction industry holds. We know that it will be a slow return, but this industry will be back to where it was. This industry is too big and too strong for it not to come back; construction is the foundation of our economy. We look at it as a “glass half full, not half empty.”

Getz: There will always be a desire for masonry buildings and a need for preserving existing masonry structures. As an industry, there are two trains of thought that require a conscientious effort on our part to stay above the status quo. One is to remain empathic with building owners' needs for cost-effective masonry construction designs and techniques, and to continue to educate the tradesman on new materials and product technologies. The result of our efforts helps propel the customers’ decision toward a value-added masonry building investment. Second, we cannot become complacent with alternative material construction products intended to replicate the masonry “look,” yet fall far below the performance benefits of authentic masonry.

Ripley: We feel that the future of the masonry/construction industries is bright, but challenging. The industry has the most visually appealing product for veneers, no contest. Our history of providing products that endure all types of weather conditions, fire and most seismic reactions are proof of a long-lasting, superior product.

Unfortunately, during an extended slow period, companies have to make some tough decisions. Keeping your core group intact is essential in surviving now and in the future. It may mean taking work at lower margins or working in areas that are further from home, but it is a must to continue to generate revenues with key personnel to survive.

Originally published in Masonry magazine.

About the Author

Jennifer Morrell was the editor of Masonry magazine. She has 20 years of experience in the publishing industry as a writer and editor, covering such topics as real estate and construction, insurance, health care, relationships and sports. A graduate of The University of Georgia’s Grady College of Journalism, she earned a Bachelor of Arts degree in magazines and is an award-winning newspaper columnist.