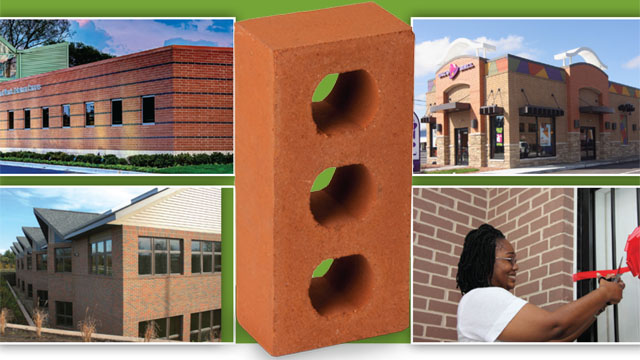

Life cycle assessment confirms environmental performance of CalStar Brick

Third-party-verified Environmental Product Declaration shows elimination of firing contributes to 81% embodied energy reduction

CalStar Products released an Environmental Product Declaration (EPD) of its brick, which details the results of an intensive, months-long life cycle assessment (LCA) conducted by leading architecture firm Perkins+Will. The LCA verifies the significant environmental benefits of the company’s non-fired brick. The EPD is the first to be published within the brick category and is one of only a handful currently available in the greater building products industry.

Data from the life cycle assessment show the cradle-to-gate (raw material extraction and transportation, and manufacturing) CO2 emissions for a single CalStar brick to be 0.13 pound, versus 0.81 pound for a single clay brick (as noted in the NIST BEES Online database). For cradle-to-gate embodied energy, the LCA shows that a single CalStar brick requires 1,203 BTU of energy vs. the 6,251 BTU the traditional process requires. Based on these data, CalStar bricks deliver an 84% lower carbon footprint and use 81% less manufacturing energy, with similar aesthetics and performance as traditional fired clay bricks.

“Traditional bricks are beautiful and durable, and now we’ve made them more sustainable,” said Joel Rood, CalStar Products CEO. “CalStar’s mission of reducing the environmental impact of building products can only be quantified with third-party-verified, completely transparent product benchmarking. This is why we made this project a top priority. The results of the LCA confirm that selecting CalStar over traditional options contributes to quantifiable reduction in a project’s environmental footprint.”

CalStar Products achieves these savings through a proprietary manufacturing process that incorporates fly ash, rather than clay, as the binder. This replacement eliminates the need for firing: CalStar bricks are cured overnight at temperatures below 200° F, while clay bricks are fired for up to four days at temperatures reaching 2,000° F. Along with energy savings and emissions reduction, each CalStar brick incorporates 37% recycled content, diverting tons of waste from landfills each year.

The CalStar life cycle assessment was performed by Perkins+Will using data sets from GaBi 5.0 software. The resulting EPD was verified under the SMaRT© Certified rating system operated by the Institute for Market Transformation to Sustainability (MTS), an EPD program operator.

To read the full CalStar Products Environmental Product Declaration, visit www.calstarproducts.com/epd.

About the Author

CalStar Products, Inc. develops and manufactures sustainable building products that allow customers to dramatically reduce the energy and carbon footprint of their projects and incorporate significant recycled materials, without compromising building performance or budgets. Visit www.calstarproducts.com to learn more.