When asked about Indiana Limestone and our industry, we may get a little long-winded, but usually the recipient is appreciative when we bring up one or two points they weren’t aware of, so here it goes!

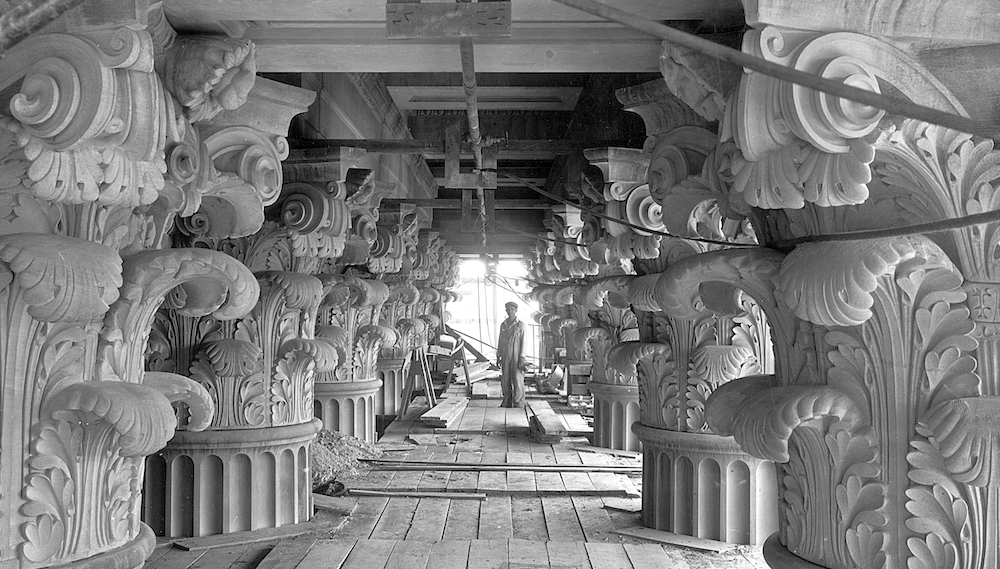

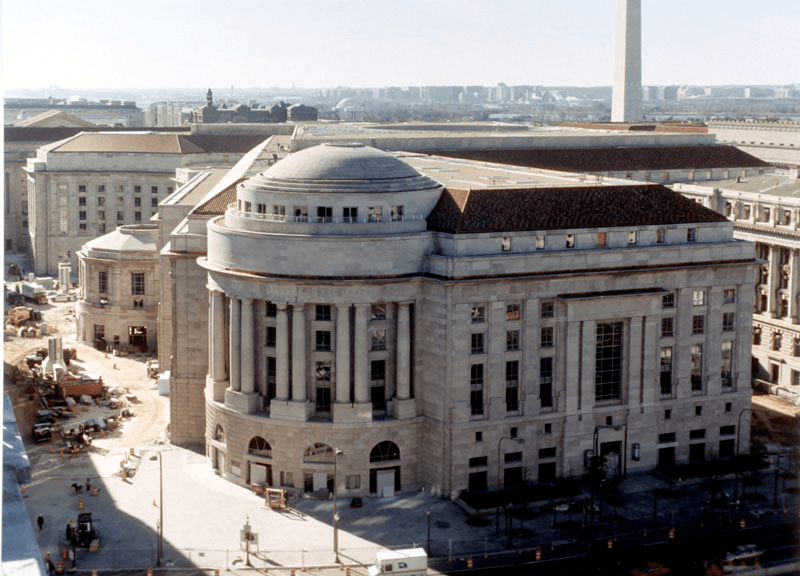

Over the last 190 years, natural dimension limestone quarried from the Salem deposit in south-central Indiana, commonly known as “Indiana limestone”, has firmly established itself into the building language of the United States & Canada, but is also found on projects around the world. By conservative estimate, the number of projects run into the tens-of-thousands. Of note: The Empire State Building, The U.S. National Cathedral, The National Archives, Numerous State Capitol buildings, Major train stations, Museums, Cathedrals, Corporate and Education Buildings as well as residences from small single-family homes to large mansions such as the Biltmore Estate in North Carolina.

Asheville, NC

Richard Morris Hunt

We are asked on occasion if demand for the stone is still high, how much is left, or even if the industry is still in business. Though our industry (like every other industry) has had its inevitable ups and downs, it has survived a civil war, two world wars, and a major depression. Through it all, the industry continues to survive and thrive. The stone supply is extensive over the 37-mile long and 3-mile wide deposit, and though estimates vary, it should easily meet demand for the next 100 or more years. The most obvious threat comes from surrounding development.

Washington, DC

John Russel Pope

Constructed 1931- 1935

PHYSICAL CHARACTERISTICS

Indiana limestone is classified under the ASTM C-568 as a “Type-II” Medium Density Dimension Limestone. This classification establishes the minimum physical performance characteristics the stone should meet.

***It should be noted here that our ILIAI Handbook1 publishes 700 psi minimum for Modulus of Rupture and 144 lbs/cu-ft for weight which are more critical than the ASTM C-568 definition for “Type-II” stone. These adjustments were made by our ILIAI Technical Committees, who edit the Handbook, utilizing decades of test data.

We often see specifications that demand a higher density or compressive strength than published for Indiana limestone. Though some samples will yield higher test results, Indiana limestone CANNOT be specified to meet any more critical performance than laid forth in our ILIAI Handbook. This would be like looking for a needle in the haystack.

We explain the difference between gravity “supports” and lateral “tie-backs” or “anchors”. We also discuss the general idea of providing four points of attachment for panels (two engagements in the bottom bed and two in the top bed of the stone). Any more is typically redundant and undesirable. Any less may be insufficient.

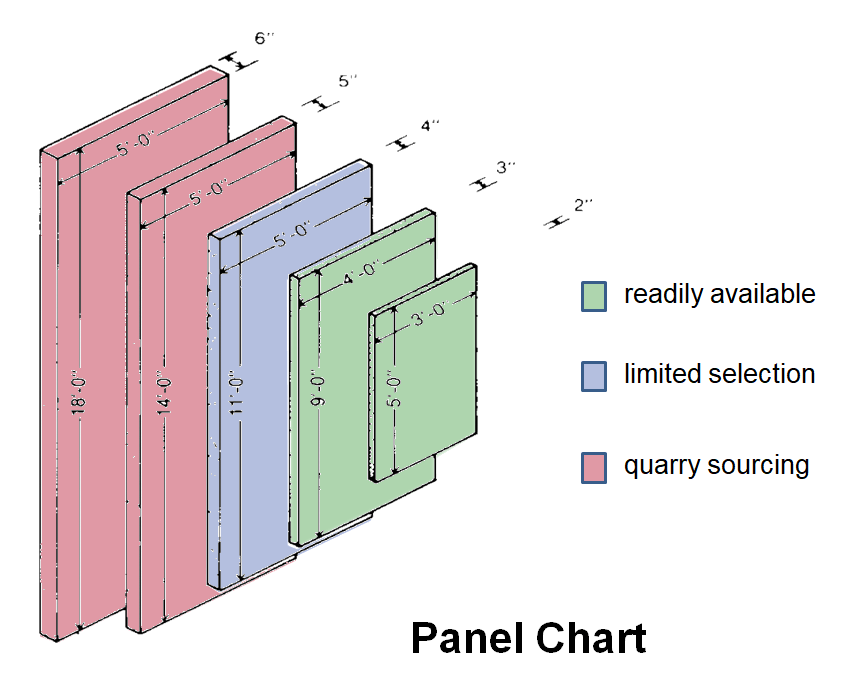

Regarding panel sizes and thickness, it’s important to understand the implications of designing very large units into a design. To address one component of this, we publish a panel chart which simply provides a “rule of thumb” on panel face dimensions and recommended thickness relating to efficient fabrication and handling. (i.e., the larger the face dimension, the thicker the panel will need to be to better survive handling in fabrication, shipping, and erection).

We have been working to further clarify this panel chart in contemporary practice. To be clear, though we CANNOT imply larger panels are not achievable, it is important to understand the general implication of face panel size in design and how this may impact ready availability and cost of the stone. Very large panel designs may simply not be achievable with existing stock which may imply additional cost and time, or a change in design strategy.

We understand clearly, that during the bid-document phase of a project, the architect cannot reasonably be expected design (& engineer) shop drawings for the stone or anchorage, but should attempt to hit as close to center of the target as possible, to avoid unnecessary changes in scope, schedule and cost after bid day. To that end, we emphasize that ALL Indiana Limestone cut for dimension stone application should meet the requirements of ASTM C-568 and the properties laid forth in our ILIAI Handbook.

With the physical design considerations put aside, the design team can then focus on; Aesthetics, Availability, Scope, Schedule, & Cost.

Aesthetics – Indiana limestone is generally defined by color (gray or buff), in combination with a definition of grain structure (Select, Standard, or Rustic as defined in the ILIAI Handbook page-10). It can also be defined as (Variegated) which allows for any of the described colors and grain structures to come forth in the selection. It should be noted that some individual quarries and fabricators market branded products specific to their operation, but still fall within the definition of Indiana limestone. We must defer to the producer in these cases.

Availability – Though not generally considered a commodity, there are periods where the market places pressure on the availability of a specific stone specification driven by; current (available) stock, current quarry yields (gray, buff, variegated), large project allocation, and/or current design trends. Very large dimension stone panel requirements may be directly impacted by availability of existing stock, not to mention stock within a specific range of color/grade.

Scope – Requirements of the project hand. A smaller project, such as a monument sign will typically have little issue in getting a specific stone color & grade defined to satisfy the project, but if we have a large corporate office building or similar project covered with thousands of square feet of stone, the availability of a specific aesthetic may be more challenging. Being a natural stone, a specific selection of color/grade will have a range that may have to allow for more variation. The inherent advantage of Indiana limestone, however, is that the stone will tend to mellow and blend to a pleasing palette over time.

Pei Cobb Freed & Partners / Ellerbe Becket

Completing the Federal Triangle (Opened in May 1998)

Variegated Indiana Limestone

Schedule – By virtue of the proceeding 3-factors alone, schedule may be directly impacted. IF schedule is the driving the critical path of a project, one or more of the above may have to be allowed some flexibility.

Cost – Along with schedule, this point is commonly critical in the determination of a project’s direction. Though we cannot discuss specific pricing points, the basic premise that a Variegated selection, which allows for all color and grain structure in the project, may be the most cost-effective solution. This selection is required to be structurally compliant, but it does not require the stone to be sorted to meet a specific range. The advantage is that it does not have to be handled as much as a specific selection would, thus reducing wasted time and material.

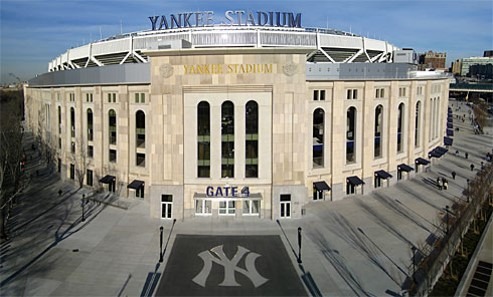

Indiana Limestone faced Precast panel

Populous

Opened 2009

Importance in detailing

The ILIAI was created 90-years ago to promote our industry, but more importantly, support the designers, masons who install the stone, as well as end-users. Though we cannot design or engineer your project, the ILIAI will provide a gratis review of drawings and specifications against the ILIAI Handbook and provide feedback for further consideration by the project team.

As with ANY building product, understanding of appropriate application and installation detailing is critical to good outcome and long-term performance.

Toronto, CAN

KPMB Architects

Expansion completed 2006

Some of the typical points we cover are:

Stone specifications

- Insure the color & grade description align with the project intent.

- Qualify the physical performance criteria align with published minimum standards for this classification of stone.

- Review testing requirements that are often boiler-plate and unnecessary, saving money & time.

- Review setting materials; shims, mortars, sealants, damp-proofing, etc. to align with drawings and best practices.

- Review handling and preparation procedures.

- Review cleaning and maintenance protocol.

- Depending on the scope of the project, we may suggest that an Engineering review of stone and anchorage shop drawings are performed by a cladding designer experienced with natural stone (typically included in the masonry bid).

Las Vegas, NV

David M. Schwarz Architects

Opened 2012

Drawing package

- Review elevations for; jointing patterns, panel face dimensions and stacking heights to see if they align with what is typical or reasonably achievable.

- Note how surrounding stone to openings (heads, lintels, & jambs) appear to be supported.

- Review the backup system to better understand how the stone is supported in gravity and tied-back laterally in the design.

- Note issues of stress-inducing conditions that have the potential to impact the stone.

- Note issues of design application that may not be best-suited to the material.

- Make observations on potential issues in handing and erection implied by the design.

- Note observations on; damp-proofing, expansion joint locations, flashings, etc.

It is most reassuring when we receive calls for support at the front-end of a project when the design team makes a sincere effort to design appropriately and ensure a successful outcome in the use of Indiana limestone the entire team can be proud of.

We are here to help, so please don’t hesitate to call on us.

We encourage you to visit our web-site (www.iliai.com) and download our current (22nd) Edition ILI Handbook which contains information and details on most of the topics discussed above.

Thank you for choosing Indiana Limestone!

Todd Schnatzmeyer, AIA/LEED-AP

Executive Director

todd@iliai.com

- The Indiana Limestone Institute of America, Inc. Handbook, currently in its 22nd