Since childhood, the bricks and blocks, the lime and cement of masonry restoration have seemed as integral to Tom Vacala as flesh and bones. The industry fuels him because he loves the historical side of it, which sometimes makes him feel a little like a sleuth and sometimes like Indiana Jones.

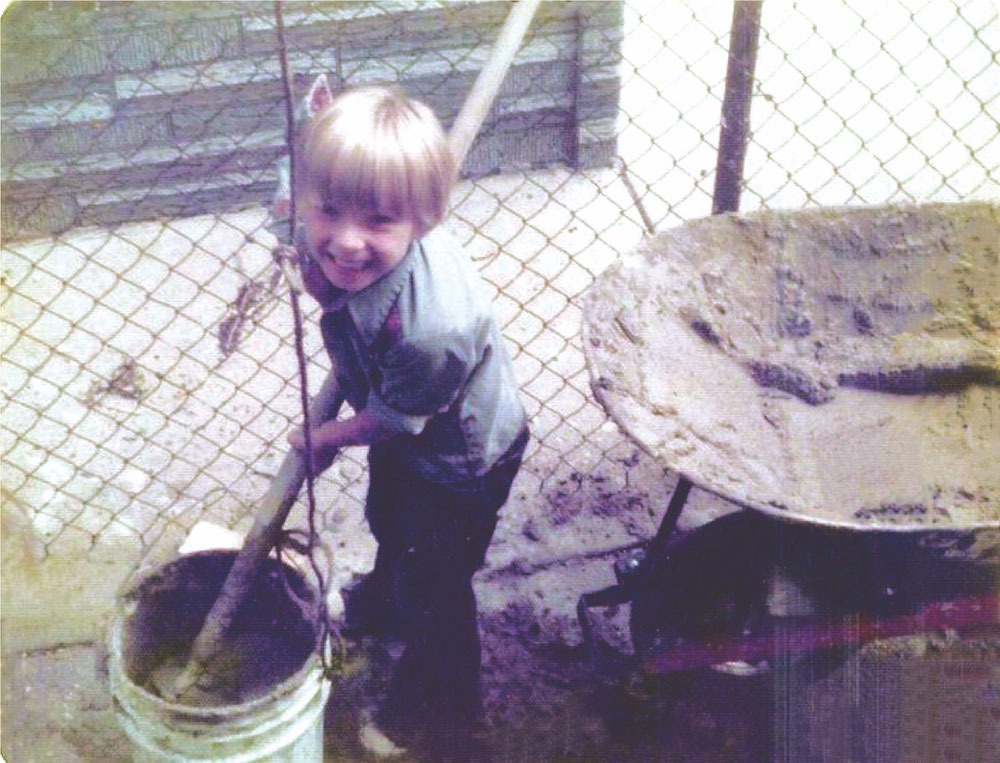

“I come from a family of 11 children— eight boys and three girls. Eight of us make a living in masonry. I actually have a picture of myself as a boy mixing mortar for one of my brothers’ side jobs,” says Tom. “Throughout high school I worked on weekends and summer with my brothers. After graduation I went to work for my brother Larry, starting in residential and then working my way into commercial restoration.”

Working beside two brothers, Larry and Mike. Tom serves as vice president of operations for Restore Masonry LLC., an award-winning masonry rehabilitation and restoration firm based in Chicago, Ill. Tom has done restoration and renovation work on commercial and residential projects. Projects Tom has been involved in have ranged from historical landmarks to residences and institutions. The Howard Street “L” Stop, North Park Village Auditorium, and Consulate General of the Republic of Poland, Schools, all in the Chicago area, are all within his portfolio.

Sometimes Awards

Lane Tech High School, also in Chicago, marks one project Tom is particularly proud of. The International Union of Bricklayers and Allied Craftworkers gave it the best restoration/rehabilitation/maintenance project award for 2017. The college prep school houses 4,800 students, faculty, and staff members and spans 607,500 square feet. The masonry exterior of the building, erected in 1934, had deteriorated by the Midwestern climate. So Tom and The Restore Masonry Team rolled up their sleeves and got to work on the 16-month project, working throughout the school year.

The project included several components:

- rebuilding more than 6,000 linear feet of brick parapet walls to accommodate a new roofing system

- demolish then reconstruct more than 34,000 square feet of masonry buttresses to expose structural steel and conduct repairs

- restore and repair more than 15,000 pieces of the facade’s terra cotta

- 163,000 square feet of grinding and tuckpointing

- repair and replace 5,400 linear feet of steel lintels and 18,700 linear feet of flashing.

“That was a lot of brick… a lot of brick,” says Tom. Indeed: the project required laying 1.1 million new ones. He credits earning projects like this and then the follow up awards to his team’s skillful masonry practices. They have been trained well, getting onsite training with in-shop experts, with manufacturer reps, and architects.

“They’ve learned a lot at the union training center and in the field,” he says. “When they open up a wall or unwrap a veneer on a wall, they recognize issues. They can not only properly identify the problem, but they come up with solutions to help put it back together properly.”

Abundant and purposeful training has equipped Tom and his team with a variety of masonry restoration techniques that depend on the existing mortar, how the building was built, and the architect’s design. His teams carefully consider a building’s architectural heritage and aesthetic qualities. Their work is complex, yet it requires sensitivity and a concerted effort to find solutions that simultaneously strengthen and protect buildings. Their job is to reveal a building’s original beauty.

To that end, there are many possible tasks to restoration work:

- tuck pointing

- brick replacement

- stone repair or replacement

- epoxy injections in concrete

- terra cotta repair or replacement

- lintel repair

- and cleaning.

The glue between

Naturally, mortar comprises a significant element of that work. In the Midwest until the late 19th century, it contained one part lime and three parts sand. Today’s masons commonly mix mortar with a bit less lime and at least one part hydraulic cement. This retains the permeability and compressive strength of existing masonry units.

“We remove a lot of existing mortar between the bricks and install new mortar. On historical buildings we use lime putty mortar, a really soft mortar. That’s the way many buildings were done years and years ago. Their mortar was softer than the brick, which allows for movement, especially in the freeze-thaw climate of the Midwest.”

Because the ground and brick walls expand and contract between summer and winter, it’s imperative to create weak spots without ruining the integrity and sturdiness of the building, he says. Lime putty mortars are useful for that because they allow for movement. Using lime putty mortars, the mortar cracks instead of the actual brick.

Working with steel

Sometimes, however, aging happens worse on the interior than the exterior. That’s especially true when masonry is combined with steel. Whether they’re in a cavity wall or solid masonry wall, a lintel or other aperture, these age spots are prone to deterioration.

“Brick is an absorbent material. It’ll absorb water even though it’s breathable. If water is trapped within or behind brick in buildings in a freeze-thaw climate, that water’s expansion will damage the brick. Rusted steel has similar actions,” he says.

He often finds the steel used in lintels or other apertures have never been protected either, in which case it rusts and expands. There’s often a chain reaction within segments where steel comes in contact with masonry. When it rusts, steel can double or triple in size, which puts pressure on the brick. Pressure causes the brick to break and push outward or upward.

“In some circumstances, we may be able to leave the brick or steel in place, refabricating new steel, which we attach and repair as needed. Sometimes we use a galvanized, rust-inhibitor paint on the steel and then we’ll flash the wall properly, install weeps, and rebuild it properly.”

Almost like forensics

His work sometimes seems like a forensics exercise.

“You never know what’s going to be behind a wall,” Tom says.

Masonry work may have a system or process but Tom often finds that each building is unique. Each one has its own situations and story. Each can easily have a problem behind its walls, and he loves locating and solving them. With a little investigating and some exploring he can sniff out the clues.

“We often find walls with a lot of movement in them. Sometimes it’s due to improper installation. We’ve found in some buildings that aren’t even 10 years old that the builders just didn’t know what they were doing, or they were rushing, or they had the right materials but didn’t install them properly,” he says.

…and Indiana Jones?

Being a masonry expert like Tom means there’s at least a little Indiana Jones in your life. There may not be massive boulder threatening to flatten him and he may not be trapped in a cave with snakes, but he does find a little bit of archaeological fun to the job. That was especially true back when he worked on residential projects.

He’s been on projects on which he and a team found among the wall cavities, beer cans and pop bottles dated a hundred years ago. These cavities can feel more like time capsules.

“That was kind of cool— like the old tradesmen were leaving behind a little bit of history for us. You can tell when the house was built and how long ago they were working by looking at the dates on the bottles,” he says. “That was the work of our ancestors. They really did some amazing work and took pride in great craftsmanship.”

Another case of cool findings was at his own house, a 1890s farmhouse he’s restored. Its owner tilled for many nearby landowners, and the paperwork from those billings somehow got stuck between the walls. “It’s a fun job. We really enjoy what we do because it’s not always cut and dry. There are always challenges out there for us.”

Continuing education

Decades in masonry restoration have taught Tom many things. Here he shares some tips with anyone considering entering the field of masonry restoration.

- Restoration is quite different from new construction.

- Partner up with an existing masonry restoration company. Work alongside the crews and learn by practice. It’s a win-win for both parties.

- Research the industry. Don’t just jump into it. A restoration contractor needs to know structural load calculations, structural shoring, steel fabrication and repair, and many other things that go far beyond rebuilding walls.

- Attend the annual MCAA Convention in Las Vegas.

- Take classes in masonry restoration.

- While bricks and mortar are some of the first building tools humans have used, masonry restoration increasingly uses software and technology.