Strengthening URM with GFRP Composites and Ductile Connections

Introduction

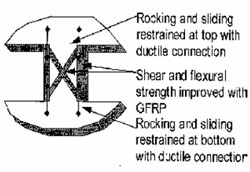

Figure 1. Hybrid Strengthening Concept

Figure 2. Steel Reinforcement Connection

Figure 3. Ductile Connection Formed with Reinforcing Steel Left: Bar epoxy grouted into foundation Right: Grout placed around bar GRFP is then placed over grout to form a "lap splice"

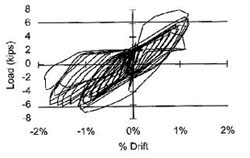

Figure 4. Hysteresis for final test specimen

|

FRP And Steel Combined

Externally applied FRP composites can be used to improve the in-plane shear and flexural strength of piers and shear walls (Marshall et al. 1999 and Abrams 1999). In addition, the composites can prevent dangerous debris from falling during and after damaging ground motion. Although FRP composites can greatly strengthen the masonry component, ductility is not improved significantly due to the brittle nature of composites.

Research conducted at the University of Wyoming has focused on a hybrid strengthening system that contains both FRP composites and steel. Figure 1 illustrates the concept of surface applied FRP composites used in combination with a ductile connection at the pier or shear wall boundary. The composite ensures that the strength of the pier is adequate to resist the shear and flexural stresses experienced during ground motion. The ductile connection is designed to yield before the composite fails. The connection increases the lateral capacity of the pier with the added benefit of a ductile failure mode, ensuring both displacement capacity and energy dissipation. This alternative is attractive because the difficult installation sometimes necessary for steel systems is isolated to discrete locations on the pier boundary. In addition, it allows the system to be installed on a single face rather than requiring access to both faces.

EXPERIMENTAL PROGRAM

Specimen Construction

Four unreinforced 8-in. single-wythe concrete masonry walls laid in running bond with a full mortar bed were tested. All test specimens measured 88-in. tall by 64-in. (2.2-m x 1.6-m) wide. Test specimens were strengthened with 3.5-in wide unidirectional glass fiber strips. The GFRP composite was formed and adhered to one face of the wall with a two-part epoxy. The composite was placed perpendicular to the bed joints at the end of the specimen to strengthen the flexural failure mode. Diagonal strips were also applied to strengthen the shear failure mode.

External and internal steel connections were used to anchor the vertical GFRP composite strips to the foundation. The external connection was a steel angle-plate assembly, and the internal connection was a steel reinforcing bar (see Figure 3). To force the ductile failure sought, the connections were designed to yield prior to the failure of the FRP strengthening.

The test specimens were tested cyclically under displacement control. It was found that the strengthening system performed well. The results of the last test are shown in Figure 4.

The eccentricity of the "lap-splice" between the reinforcing bar and GFRP composite caused out-of-plane displacement at the critical section, leading to instability in an earlier specimen. The eccentricity was reduced in subsequent specimens, improving the displacement capacity of the specimen.

Application of the GFRP composite and ductile connections provided an increase in lateral capacity that was nearly double that of the unreinforced wall. The largest drift capacity (1.7%) was obtained on the final specimen with the internal connection. The maximum drift was reached when the reinforcing bar ruptured. Equations for estimating the flexural capacity were also developed and agreed well with the experimental results.

Acknowledgements

The author would like to acknowledge and thank the Market Development Alliance (MDA), the National Concrete Masonry Association (NCMA), and the National Science Foundation (CAREER grant CMS-9734227) for funding this project. A special thanks is extended to the MDA's FRP/Unreinforced Masonry Technical Team for their input and suggestions.

About the Author

Dr. Hamilton is Assistant Professor of Structural Engineering at the University of Wyoming.