Building for Sustainable Masonry Construction

incorporate a closed loop attachment system to prevent tie disengagement, thus ensuring code conformance.

If sustainability is partially defined in terms of longevity, then masonry must be near the top of the list. Everyone knows that brick and block buildings are long lasting and extremely durable. But there are many other aspects to a masonry wall assembly that contribute to a properly functioning and sustainable structure.

According to the U.S. Green Building Council (USGBC), "The Leadership in Energy and Environmental Design (LEED) Green Building Rating System is the nationally accepted benchmark for the design, construction and operation of high-performance green buildings." LEED promotes a whole building approach to sustainable design in six categories, of which brick and masonry can directly impact four: energy efficiency and renewable energy; conservation of materials and resources; indoor environmental quality; and innovation and design process.

Masonry and brick are energy-efficient materials with insulating values and high thermal mass, which may allow a reduction in the size of the building's HVAC system. Brick and masonry are among the most salvageable building materials, thus diverting waste from landfills. Brick and masonry offer unsurpassed lifecycle cost advantages with minimal maintenance issues. Also, the ingredients of masonry and mortar are inert, non-toxic and promote excellent indoor air quality. Because masonry is normally constructed on-site, architectural expression can be achieved to include block and/or brick, plus colored mortar can match or complement the look of the masonry.

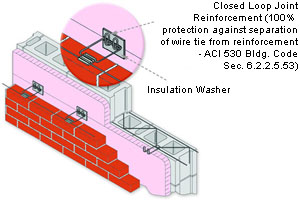

Most masonry wall assemblies require some form of structural reinforcement to increase the longevity of the building. In most cases, the wire reinforcement and masonry anchoring systems used to secure these walls are manufactured of steel fabricated from 99 percent post-industrial recycled material. Multi-wythe masonry walls require careful consideration to "tie together" the different wythes into a single, functioning wall. Newer adjustable anchoring systems incorporate a closed loop attachment system to prevent tie disengagement, thus ensuring code conformance. Proper selection of the reinforcement and anchoring systems is a critical component of a sustainable wall assembly, and must take into account possible seismic and wind load requirements in certain geographic regions.

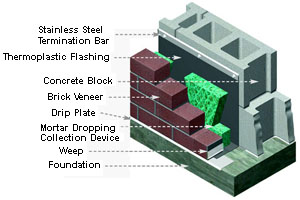

Another aspect of the masonry wall that is critical to long-term sustainability is prevention of moisture infiltration and proper drainage of the wall assembly. Cavity wall design has been popular for more than 50 years, but, recently, we have seen a greater interest in researching the "inner-workings" of the wall. Air/vapor barriers, through-wall flashings, mortar collection devices, weep holes and vents are all part of a successfully functioning wall, and it must be determined how these products perform together to create a sustainable, water-tight wall.

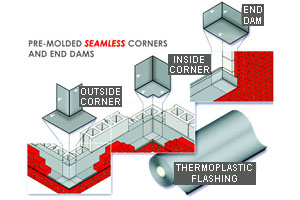

Flashings have long been used in masonry construction and have, historically, consisted of hard metals, laminated metal products and flexible rubber materials. Today's newer flashings include thermoplastic membranes with clear adhesive that have tremendous UV stability and seamless pre-formed shapes for detail points, with the intention of creating a "user friendly" total flashing system.

Air/vapor barriers, new ventilation techniques in the cavity and an improved understanding of insulating concepts have taken wall assembly design into the 21st century as we strive to meet the goals of achieving a truly high-performance building.

These accessory components of masonry wall design and construction are a critical part of building healthy and sustainable structures for the future.

About the Author

Christopher Bupp is the head of Architectural Services for Hohmann & Barnard, Inc. The building envelope has been his primary area of expertise. Contact Chris at chrisb@h-b.com.