August 27, 2012 7:00 AM CDT

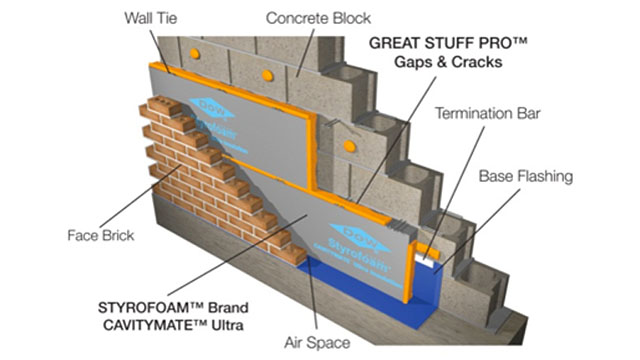

The Ultra Air Barrier Wall System delivers exceptional long-term thermal insulating performance and excellent air/vapor-barrier capability in brick and block walls using trusted and familiar products: STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation and GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant.**

For more information, here is a link to Issue 1 feature article ‘The Ultra Air Barrier Wall System: Your Best Bet for a Better Wall’.

Dow has listened. We understand that you are looking for:

Available in thicknesses up to 3” to meet the required R-value***, this rigid extruded polystyrene foam insulation comes in 15 ¾” board widths to easily fit between the wall ties and accommodate any slight imperfections. The time needed to adjust ties up and down is reduced when installing the insulation.

GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant

The minimal-expanding, single-component polyurethane foam sealant is used between the insulation board joints, around penetrations and for holding the insulation in place to the underlying block wall. Easy to dispense, GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant becomes tack-free in 10-20 minutes and can be trimmed within 30 minutes, if needed. Each 24 oz can of GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant is equivalent to up to 22 quart tubes of caulking – saving time and money and reducing construction waste!2

Ultra Air Barrier Wall System

Air barrier testing to ASTM E2357 has been completed for the system. In addition, inspection is easy in the field. The contrast between the black insulation and the orange foam sealant visually highlights any disconnects in the air barrier.

1. Begin at the bottom of the wall (Course 1). Install all boards horizontally (15-3/4" x 96" orientation).

5. Install adjacent boards across the rest of the bottom course (Course 1) the same way.

6. Remaining courses: Cut the first board to be installed on the second course to 4 ft. long (or as needed) to allow for staggering of vertical joints.

All penetrations need to be sealed to the base structure to ensure that the air barrier system integrity is maintained.

See the Installation Procedures for the Ultra Air Barrier Wall System for:

The Ultra Air Barrier Wall System delivers an easy-to-install, cost-effective solution to meet code requirements for continuous insulation and air barriers in one simple solution. Learn more at www.ultrawallsystem.com or call us at 1-866-583-BLUE (2583).

NOTICE: No freedom from any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries or regions. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO EXPRESS WARRANTIES ARE GIVEN EXCEPT FOR ANY APPLICABLE WRITTEN WARRANTIES SPECIFICALLY PROVIDED BY DOW. ALL IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

WARNING: Rigid foam insulation does not constitute a working walkable surface or qualify as a fall protection product.

GREAT STUFF PRO™ Insulating Foam Sealants contain isocyanate and a flammable blowing agent. Read the label and MSDS carefully before use. Eliminate all sources of ignition before use. Wear long sleeves, gloves, and safety glasses or goggles. Provide adequate ventilation or wear proper respiratory protection. Contents under pressure.

GREAT STUFF PRO™ Gun Cleaner is flammable and contains acetone and propane. Read the label and MSDS carefully before use. Eliminate all sources of ignition before use. Wear gloves, and goggles or safety glasses. Provide adequate ventilation or wear proper respiratory protection. Contents under pressure.

Building and/or construction practices unrelated to building materials could greatly affect moisture and the potential for mold formation. No material supplier including Dow can give assurance that mold will not develop in any specific system.

1 Actual cure time will depend on temperature, relative humidity and size of the foam bead.

2 Based on estimated yield under ideal conditions using gun foam, 3/8” bead.

** Read the label and Material Safety Data Sheet carefully before use.

*** R means resistance to heat flow. The higher the R-value, the greater the insulating power. R-values are expressed in ft2• h•°F/Btu. R-value determined by ASTM C518.

®™* Trademark of The Dow Chemical Company ("Dow") or an affiliated company of Dow

Taking charge with Ultra Air Barrier Wall System

Your best bet for a better wall

By Doug Todd

Meets ASHRAE 90.1-2010 prescriptive requirements for continuous insulation and air barrier.

Today, masonry contractors are under pressure from all sides – let the Ultra Air Barrier Wall System from Dow Building Solutions help. This system helps you build your business - quickly and economically. Let Dow show you how with the Ultra Air Barrier Wall System. Trusted name. Trusted products.The Ultra Air Barrier Wall System delivers exceptional long-term thermal insulating performance and excellent air/vapor-barrier capability in brick and block walls using trusted and familiar products: STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation and GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant.**

For more information, here is a link to Issue 1 feature article ‘The Ultra Air Barrier Wall System: Your Best Bet for a Better Wall’.

Listening...

In the past, contractors often installed a separate air barrier then covered it with insulation. This two-part process was not only labor-intensive and expensive, but often created issues such as maintaining continuity during installation and commissioning. Some contractors used caulking with rigid insulation to form an air barrier but this was expensive and was not supported by required air barrier testing approvals.Dow has listened. We understand that you are looking for:

- An easy-to-install “system” that not only meets all applicable code requirements, but leverages existing building practices and can be installed under a wide set of environmental conditions.

- A design that helps you build your business by putting the air barrier component under your control but requires no expensive start-up or training costs.

- An easy-to-detail approach that can be inspected for compliance to requirements.

- Products that will allow you to directly compete with steel stud wall designs.

- Products backed by years of field-tested experience. For example, contractors already have history and experience with STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation.

And delivering...

The Ultra Air Barrier Wall System has been designed specifically for you, the masonry contractor, to deliver a proven, easy-to-install and economical system that combines a continuous, high R-value rigid insulation AND an air/vapor-barrier for brick and block cavity wall. With fewer installation steps than standard construction methods, the Ultra Air Barrier Wall System may give you the competitive advantage you need in today’s market.Two trusted products in one tested system

STYROFOAM™ Brand CAVITYMATE™ Ultra InsulationAvailable in thicknesses up to 3” to meet the required R-value***, this rigid extruded polystyrene foam insulation comes in 15 ¾” board widths to easily fit between the wall ties and accommodate any slight imperfections. The time needed to adjust ties up and down is reduced when installing the insulation.

GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant

The minimal-expanding, single-component polyurethane foam sealant is used between the insulation board joints, around penetrations and for holding the insulation in place to the underlying block wall. Easy to dispense, GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant becomes tack-free in 10-20 minutes and can be trimmed within 30 minutes, if needed. Each 24 oz can of GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant is equivalent to up to 22 quart tubes of caulking – saving time and money and reducing construction waste!2

Ultra Air Barrier Wall System

Air barrier testing to ASTM E2357 has been completed for the system. In addition, inspection is easy in the field. The contrast between the black insulation and the orange foam sealant visually highlights any disconnects in the air barrier.

Detailed installation procedures and support tools

NOTE: For additional information, Dow has a complete range of support tools, including:- Detailed Installation Guide and Videos

- Easy access to Frequently Asked Questions

- Sales literature

- CAD details

- Guide specifications

Getting ready

- Assemble materials. Here’s all that is required to install the Ultra Air Barrier Wall System on a masonry wall:

- STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation

- GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant and PRO Series Foam Dispensing Gun. Also GREAT STUFF PRO™ Gun Cleaner and GREAT STUFF PRO™ Wipes

- WEATHERMATE™ Straight Flashing (e.g., at flashings)

- Spray adhesive, such as 3M High Strength 90

- Safety gloves

- Safety glasses

- Foam cutting tools

- Prepare wall. Confirm that:

- The wall surface is clean and free of any dirt or debris

- Wall ties are properly installed and spaced

- The temperature and moisture levels fall within acceptable parameters (see Installation Procedures, Table 1)

- STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation boards are clean and dry

Installation

1. Begin at the bottom of the wall (Course 1). Install all boards horizontally (15-3/4" x 96" orientation).

Step 2

2. Apply a 1" bead of GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant on the wall above the flashing and just below the first row of wall ties.

Step 3

3. Prepare to install the first row of insulation. At a corner, leave an overhang equal to the board thickness to allow for staggering on each successive course.

Step 4

4. With the printed side facing you, angle the bottom of the insulation board into the corner of the base flashing, then rotate the top onto the wall between the brick ties. Press the board firmly against the wall to ensure contact with the insulating foam sealant.5. Install adjacent boards across the rest of the bottom course (Course 1) the same way.

6. Remaining courses: Cut the first board to be installed on the second course to 4 ft. long (or as needed) to allow for staggering of vertical joints.

Step 7

7. Apply five balls of the insulating foam sealant in the pattern shown; balls should be 2" deep by 3" wide. Install the remaining bards up and across the wall.

Step 8

8. After all boards are in position, insert the nozzle of the foam dispensing gun in between all vertical and horizontal joints and fill with the insulating foam sealant until bead of foam is visible at the surface edge.

Step 9

9. Continue to install STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation around penetrations such as ducts, electrical boxes and pipes. Fill the void between the penetration and the board with GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant.All penetrations need to be sealed to the base structure to ensure that the air barrier system integrity is maintained.

See the Installation Procedures for the Ultra Air Barrier Wall System for:

- Installing Around Windows and Doors

- Installing Around Parapet (Roof/Wall)

- Installing at Foundation

Easy product storage

STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation- Do not leave exposed to direct sunlight for more than 90 days as prolonged exposure to ultraviolet radiation may cause the surface to become faded and dusty. Brush off the dust before installation.

- When stored outdoors, cover the boards with a light-colored tarp to protect from weather and weigh down to prevent boards from being blown around by the wind.

- Always store above standing water.

- NOTE: The surface degradation will have no measurable effect on the insulating value of the plastic foam unless the deterioration is allowed to continue until actual foam thickness is lost.

- Check that surfaces are free of dust and dirt (a damp surface will not impair the bond).

- Ensure adequate ventilation and shut off all pilot lights and open flames; eliminate all sources of ignition before use. Do not smoke or use lighters or matches while dispensing foam.

- Because the foam is very sticky, do not get foam on skin. Wear gloves and goggles or safety glasses. Cured foam must be mechanically removed or allowed to wear off in time.

- Store the cans properly as the contents are under pressure.

Final thoughts

Let the combination of STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation and GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant - as well as other Dow products - work for you and deliver a winner.The Ultra Air Barrier Wall System delivers an easy-to-install, cost-effective solution to meet code requirements for continuous insulation and air barriers in one simple solution. Learn more at www.ultrawallsystem.com or call us at 1-866-583-BLUE (2583).

NOTICE: No freedom from any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer’s use and for ensuring that Customer’s workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries or regions. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO EXPRESS WARRANTIES ARE GIVEN EXCEPT FOR ANY APPLICABLE WRITTEN WARRANTIES SPECIFICALLY PROVIDED BY DOW. ALL IMPLIED WARRANTIES INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

STYROFOAM™ Brand Extruded Polystyrene Foam Insulation

CAUTION: This product is combustible and shall only be used as specified by the local building code with respect to flame spread classification and to the use of a suitable thermal barrier. For more information, consult Material Safety Data Sheet (MSDS), call Dow at 1-866-583-BLUE (2583) or contact your local building inspector. In an emergency, call 1-989-636-4400.WARNING: Rigid foam insulation does not constitute a working walkable surface or qualify as a fall protection product.

Dow Polyurethane Foam Insulation and Sealants

CAUTION: When cured, these products are combustible and will burn if exposed to open flame or sparks from high-energy sources. Do not expose to temperatures above 240ºF. For more information, consult MSDS, call Dow at 1-866-583-BLUE (2583) or contact your local building inspector. In an emergency, call 1-989-636-4400.GREAT STUFF PRO™ Insulating Foam Sealants contain isocyanate and a flammable blowing agent. Read the label and MSDS carefully before use. Eliminate all sources of ignition before use. Wear long sleeves, gloves, and safety glasses or goggles. Provide adequate ventilation or wear proper respiratory protection. Contents under pressure.

GREAT STUFF PRO™ Gun Cleaner is flammable and contains acetone and propane. Read the label and MSDS carefully before use. Eliminate all sources of ignition before use. Wear gloves, and goggles or safety glasses. Provide adequate ventilation or wear proper respiratory protection. Contents under pressure.

Building and/or construction practices unrelated to building materials could greatly affect moisture and the potential for mold formation. No material supplier including Dow can give assurance that mold will not develop in any specific system.

1 Actual cure time will depend on temperature, relative humidity and size of the foam bead.

2 Based on estimated yield under ideal conditions using gun foam, 3/8” bead.

** Read the label and Material Safety Data Sheet carefully before use.

*** R means resistance to heat flow. The higher the R-value, the greater the insulating power. R-values are expressed in ft2• h•°F/Btu. R-value determined by ASTM C518.

®™* Trademark of The Dow Chemical Company ("Dow") or an affiliated company of Dow

About the Author

Doug Todd is a Market Manager for Dow Building Solutions.